Introduction of Vacuum Gas Quenching Furnace

Vacuum gas quenching furnace is a specialized vacuum heat treatment equipment for metals. It operates by heating and quenching materials in a vacuum or low-oxygen environment to optimize high-quality metal properties and performance. The core function lies in precise vacuum control systems that rapidly and uniformly heat workpieces to high temperatures and effectively cool them with gas, enabling the desired microstructure and hardness for the workpiece. This equipment is equipped with advanced temperature monitoring and control systems, supports automated operations, ensuring process stability and repeatability, and finds wide applications in aerospace, automotive manufacturing, mold processing, and other industries to meet the high-standard material requirements of modern industrial processes.

Advantages of Brother Furnace's Vacuum Gas Quenching Furnace

High-Temperature Capability The furnace employs a design integrating graphite heating elements with graphite soft and hard felts, enabling it to achieve temperatures up to 1350°C, catering to various high-temperature heat treatment requirements and establishing an optimal environment for quenching high-performance materials. | Uniform Quenching Multiple graphite nozzle arrays are evenly dispersed within the heating chamber, ensuring consistent gas distribution throughout the quenching process. This configuration effectively achieves uniform quenching of workpieces, enhancing material structural stability and consistent performance. | Anti-Bonding Structure The hearth consists of graphite columns, a graphite hearth, and AL2O3 spacers, effectively preventing adhesion between the tray and the graphite hearth at elevated temperatures. This feature extends the equipment's lifespan and facilitates the smooth progression of the heat treatment process. |

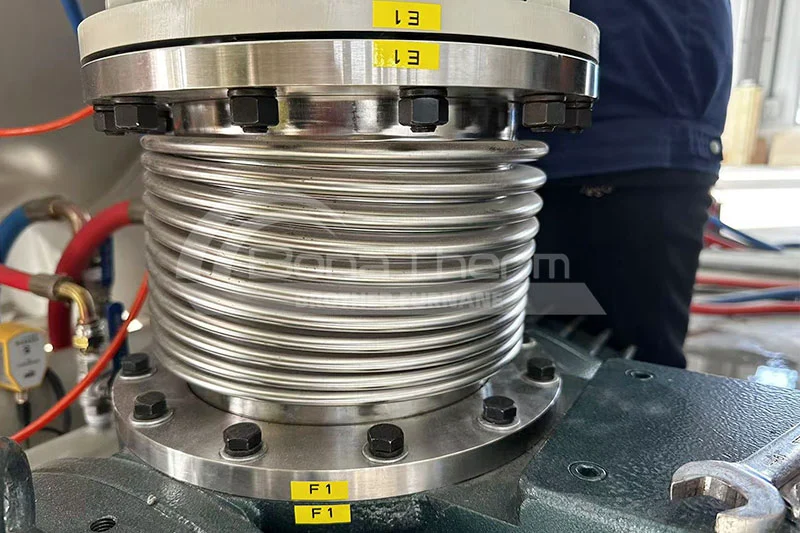

Contamination-Free Heat Field The heat field can employ high-temperature molybdenum strip heating along with molybdenum foil insulation screens to prevent volatile substances and impurities from contaminating the heat-treated workpieces. This ensures material purity at elevated temperatures, meeting the stringent requirements of high-end applications. | Efficient Gas Cooling System Equipped with a high-pressure impeller fan and multi-stage efficient copper heat exchangers, the gas cooling system utilizes high-purity nitrogen or argon for cooling. Workpieces are uniformly cooled through ducting arrangements, ensuring highly effective forced cooling. | Versatile Cooling System and Rapid Cooling The vacuum furnace features a customizable cooling setup with pressure settings between 1 to 10 bar, catering to diverse process demands. It efficiently cools from 1150°C to 250°C in under 7 minutes, ensuring enhanced productivity and shortened processing cycles. |

Applications of Vacuum Gas Quenching Furnace

High-Performance Alloys

In aerospace, automotive, and military sectors, vacuum quenching furnaces are used to treat high-temperature alloys, titanium alloys, and nickel-based alloys, enhancing their strength, toughness, and corrosion resistance.

Tool Steels and Molds

This vacuum gas quenching furnace is suitable for quenching tool steels and mold materials, effectively preventing deformation and cracks during heat treatment, thereby extending the lifespan of tools and molds.

Special Steels

In the mechanical manufacturing industry, special steels such as high-speed steels and alloy steels, when treated in a vacuum quenching furnace, can achieve higher hardness and wear resistance.

Powder Metallurgy Products

The density and mechanical properties of powder metallurgy products can be enhanced using a vacuum quenching furnace, especially yielding significant effects on the treatment of complex-shaped components.

Electrical and Electronic Industries

For materials with high electrical and thermal conductivity, such as copper-based alloys and aluminum-based alloys, a vacuum quenching furnace can improve their electrical and thermal properties.

Medical Device Materials

During the heat treatment of high-end medical device metal materials, a vacuum quenching furnace ensures material purity and stability, meeting high industry standards.

New Material Development

Vacuum quenching furnaces aid in exploring and optimizing heat treatment processes for new materials, enabling them to attain desired material characteristics.

Automotive Engine Components

For automotive engine parts like crankshafts and connecting rods, heat treatment can enhance their fatigue strength and wear resistance, thereby improving engine performance and durability.

Quenched Workpiece

|  |

Vacuum Gas Quenching Furnace VS Vacuum Oil Quenching Furnace

The two common types of vacuum quenching furnaces are vacuum gas quenching furnaces and vacuum oil quenching furnaces, with some key differences between them:

Vacuum Gas Quenching Furnace | Vacuum Oil Quenching Furnace |

|---|---|

Cooling Medium: Uses gas (usually nitrogen or argon) as the cooling medium. The cooling process is more gentle and suitable for workpieces sensitive to deformation. Cooling Rate: Relatively slower cooling rate, mainly used for materials sensitive to temperature changes or requiring toughness. Material Applicability: Suitable for various materials, including high-alloy and low-alloy steels, especially for workpieces with high oxidation requirements. Cost and Operation: Often simpler in structure, lower operating costs, and easier maintenance. | Cooling Medium: Utilizes special quenching oil for rapid cooling, ideal for workpieces requiring high hardness and wear resistance. Cooling Rate: With the involvement of quenching oil, achieves faster cooling rates, enhancing workpiece hardness. Material Applicability: Particularly suitable for high-carbon steels and alloy steels, achieving higher strength and toughness. Cost and Operation: Equipment is relatively complex, requiring more costs and operational management for oil maintenance and replacement. |

Technical Parameter

model | working size (width*height*depth) ( mm ) | Maximum temperature ( ℃ ) | Heating element | Furnace loading capacity ( kgs ) | Temperature Uniformity ( ℃ ) | Power ( kW ) _ | Ultimate vacuum degree ( Pa ) |

|---|---|---|---|---|---|---|---|

BR-QCL-334G | 300*300*450 | 1350 | graphite | 100 | ±5 | 50 | 7x10-1 |

BR-QCL-446G | 400*400*600 | 1350 | graphite | 200 | ±5 | 80 | 7x10-1 |

BR-QCL-557G | 500*500*700 | 1350 | graphite | 300 | ±5 | 120 | 7x10-1 |

BR-QCL-669G | 600*600*900 | 1350 | graphite | 500 | ±5 | 150 | 7x10-1 |

BR-QCL-8812G | 800*800*1200 | 1350 | graphite | 900 | ±5 | 260 | 7x10-1 |

model | working size (width*height*depth) ( mm ) | Maximum temperature ( ℃ ) | Heating element | Furnace loading capacity ( kgs ) | Temperature Uniformity ( ℃ ) | Power ( kW ) _ | Ultimate vacuum degree ( Pa ) |

|---|---|---|---|---|---|---|---|

BR-QCL-334M | 300*300*450 | 1350 | Molybdenum foil | 100 | ±5 | 50 | 7x10-1 |

BR-QCL-446M | 400*400*600 | 1350 | Molybdenum foil | 200 | ±5 | 80 | 7x10-1 |

BR-QCL-557M | 500*500*700 | 1350 | Molybdenum foil | 300 | ±5 | 120 | 7x10-1 |

BR-QCL-669M | 600*600*900 | 1350 | Molybdenum foil | 500 | ±5 | 150 | 7x10-1 |

BR-QCL-8812M | 800*800*1200 | 1350 | Molybdenum foil | 900 | ±5 | 260 | 7x10-1 |

Get Inquiry

Get Inquiry Send Email

Send Email