The Application and Advantages of Titanium Alloys in Vacuum Brazing Furnaces

BROTHER FURNACE

BROTHER FURNACE

2024-12-18 19:31

2024-12-18 19:31

Titanium alloys, renowned for their exceptional mechanical properties, corrosion resistance, and lightweight characteristics, are widely used in numerous high-demand industries. To meet the welding requirements of titanium alloys, vacuum brazing technology has become a crucial method for precise joining. This article will provide a detailed overview of the applications and advantages of titanium alloys, particularly in vacuum brazing processes.

Introduction to Titanium Alloys

Titanium alloys comprise titanium and other metallic elements such as aluminum, vanadium, and molybdenum. Titanium is known for its excellent corrosion resistance, high strength-to-weight ratio, and high-temperature stability. Due to these outstanding properties, titanium alloys have become indispensable materials in modern industries, especially in the aerospace, medical, and chemical sectors.

Titanium alloys can be classified into three main categories: alpha alloys, beta alloys, and alpha-beta alloys. Each type of titanium alloy possesses distinct characteristics to meet different industrial requirements. One of the main challenges in working with titanium alloys lies in their unique behavior during welding, particularly brazing, where avoiding oxidation and maintaining the material’s excellent properties is crucial.

Industries That Use Titanium Alloys

Titanium alloys are used extensively in the following industries due to their unique properties:

Aerospace

Titanium alloys are widely used in the aerospace industry for critical components such as aircraft frames, engine parts, and missile components. Their high strength-to-weight ratio and resistance to high temperatures allow them to withstand extreme conditions, ensuring the safety and reliability of the parts.

Medical Industry

Due to their excellent biocompatibility, titanium alloys are vital in the medical field, especially in the production of artificial joints, dental implants, and surgical instruments. Their corrosion resistance ensures long-term stability when used in the human body, reducing the likelihood of rejection.

Chemical Equipment

Titanium alloys are highly resistant to corrosion, making them ideal for use in chemical processing equipment such as pipes, reactors, and heat exchangers. Their ability to perform well in harsh chemical environments makes them a valuable material in chemical industries.

Energy Sector

Titanium alloys are used in the oil, natural gas, and renewable energy industries, especially in environments with high temperature, pressure, and corrosion. Their durability and resistance to degradation significantly extend the lifespan and stability of critical equipment.

Marine Engineering

In marine engineering, titanium alloys are used in offshore platforms, diving equipment, and subsea pipelines. Their excellent resistance to seawater corrosion provides strong technical support for offshore operations.

Advantages of Vacuum Brazing Titanium Alloys

In the processing of titanium alloys, traditional welding methods often face challenges such as oxidation, thermal cracking, and embrittlement. In contrast, vacuum brazing technology offers significant advantages for joining titanium alloys:

Prevention of Oxidation and Embrittlement

Titanium alloys are highly sensitive to oxygen, and exposure to air can lead to the formation of an oxide layer, which degrades the quality of the weld. The vacuum brazing process effectively prevents the interaction of oxygen with titanium alloys, preserving their excellent properties and preventing embrittlement.

Precise Temperature Control

Vacuum brazing furnaces provide precise temperature control systems that help avoid overheating or underheating during the welding process. The efficient temperature control ensures uniform distribution of heat, which further improves the strength and stability of the brazed joints.

High-Quality Joints

Vacuum brazing uses low-melting-point brazing materials, enabling high-quality joints at lower temperatures and preventing overheating of the titanium alloy. By selecting the appropriate brazing material, the brazed area achieves high strength and durability.

No Heat-Affected Zone (HAZ)

Unlike traditional welding methods, vacuum brazing avoids the creation of a heat-affected zone (HAZ), meaning that the titanium alloy does not undergo any degradation of its structural properties. The precise temperature control during brazing prevents thermal cracking and other welding defects.

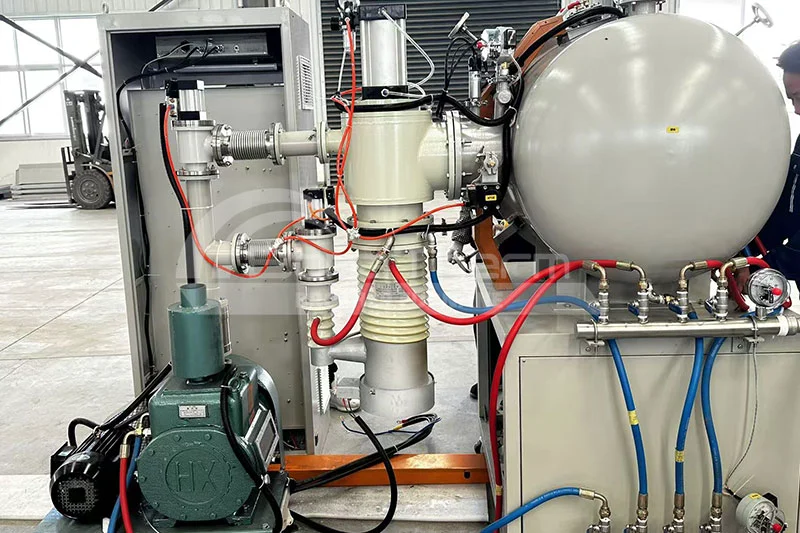

Brother Furnace's Stainless Steel Vacuum Brazing Furnace

|  |

Brother Furnace’s stainless steel vacuum brazing furnace, an efficient tool for titanium alloy brazing, provides an ideal processing environment. Its main features include:

High-Precision Temperature Control System

Brother Furnace’s vacuum brazing furnace is equipped with an advanced temperature control system that ensures uniformity and accuracy throughout the welding process. Precise temperature control guarantees the welding quality and enhances the strength of the brazed joints.

Atmosphere Control Functionality

The precise control of the furnace atmosphere is key in titanium alloy brazing. Brother Furnace’s vacuum brazing furnace supports both vacuum and inert gas environments, effectively preventing oxidation and ensuring the perfect surface quality of titanium alloys.

High Efficiency and Energy Saving

The furnace features a highly efficient heating system that reaches the set temperature in a short time, significantly boosting production efficiency. Additionally, its energy-saving design ensures that the equipment operates at high performance while maintaining low energy consumption.

Adaptability to Various Brazing Requirements

Brother Furnace’s vacuum brazing furnace is versatile and can be used for various brazing materials and processes, particularly the high-precision joining of titanium alloys, meeting the diverse demands of different industrial applications.

Conclusion

Titanium alloys, with their exceptional properties, play a vital role in several high-end industries. To ensure the quality of titanium alloy welding, vacuum brazing technology has become the ideal choice. Brother Furnace’s vacuum brazing furnace maximizes the advantages of vacuum brazing, preventing oxidation and embrittlement, and achieving high-quality, high-strength titanium alloy joints. Brother Furnace welcomes clients seeking superior vacuum brazing solutions to contact us for the most professional furnace solutions available globally.