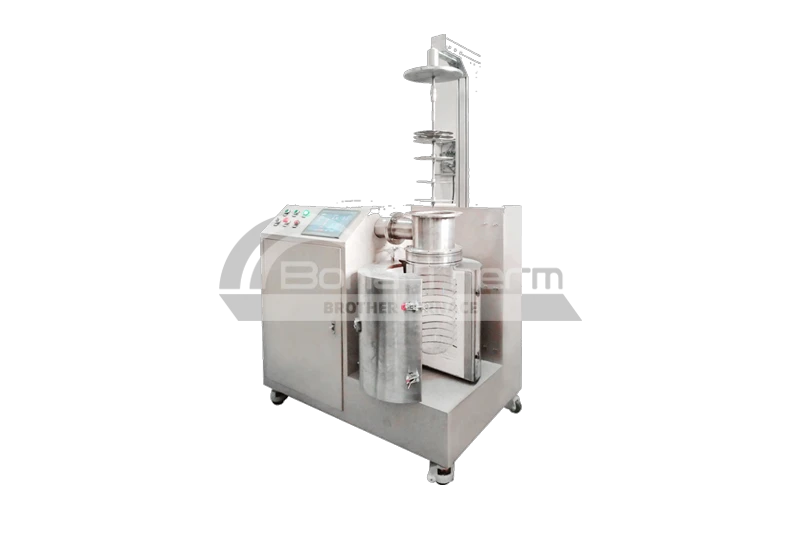

Introduction of Vacuum Brazing Furnace

The vacuum brazing furnace, featuring a heat-resistant steel hot field, is designed for high-precision brazing applications where temperature uniformity and clean processing environments are essential. With a maximum operating temperature of up to 750℃. It is particularly suitable for welding heat-resistant steel. It mainly uses a vacuum environment to improve welding quality and ensure that oxidation and contamination during the welding process are minimized.

|  |

Features

1. Construction and Heating System

The furnace features a stainless steel chamber and utilizes electric heating alloy tubes, with the maximum temperature reaching up to 750°C. The heating is achieved through ring-shaped alloy tubes, providing high uniformity with temperature variations within ±5°C.

2. User Interface and Control System

The furnace is equipped with a high-definition touchscreen interface and an operating system developed in-house. It also includes a PLC (Programmable Logic Controller) automatic control system for precise and reliable operation.

3. Vacuum System

The clean stainless steel chamber is complemented by a vacuum system consisting of a mechanical pump and a diffusion pump, achieving an ultimate vacuum of up to 7x10⁻³ Pa (under unloaded, cold conditions).

4. Economic Efficiency

Compared to molybdenum foil vacuum furnaces, this electric furnace offers lower power consumption and cost, making it a practical and economical choice for low-temperature brazing applications.

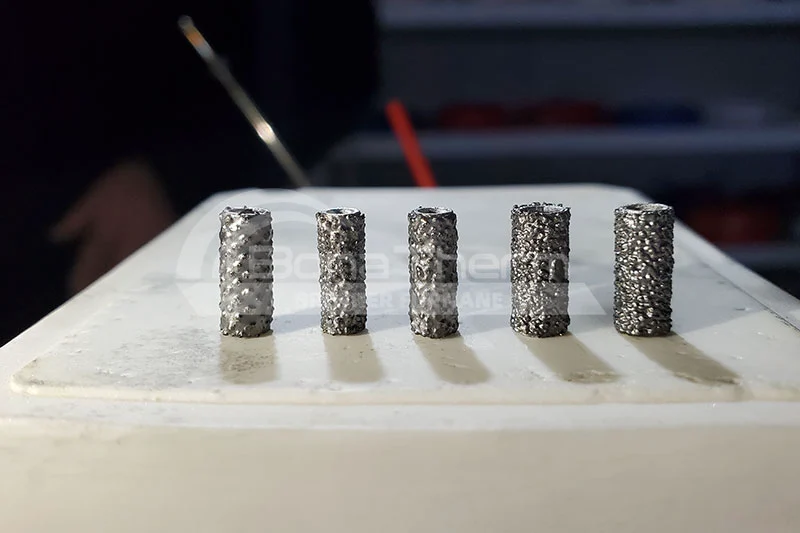

Materials after Brazing

|  |

Optional accessories

- External rapid cooling system; from brazing temperature to 180 degrees in less than 1 hour.

- Chiller

- A stainless steel multi-layer material rack is convenient for placing multi-layer brazing workpieces.

Low-temperature aluminum zinc-based flux:

Flux composition | Color | Melting temp. |

|---|---|---|

AlSi12 | Black | 580℃ |

AlSiCu | Black | 480-550℃ |

Zn98Al | Black | 450℃ |

ZnSnCu | Black | 380℃ |

Technical parameters

Model | Chamber size | Temp. | Power | Voltage |

|---|---|---|---|---|

BR-QHS-223 | 200*200*300mm | 750℃ | 3kW | 380V |

BR-QHS-334 | 300*300*400mm | 750℃ | 6kW | 380V |

BR-QHS-446 | 400*400*600mm | 750℃ | 12kW | 380V |

BR-QHS-557 | 500*500*700mm | 750℃ | 18kW | 380V |

BR-QHS-669 | 600*600*900mm | 750℃ | 28kW | 380V |