Principle of Debinding and Sintering of Ceramics

BROTHER FURNACE

BROTHER FURNACE

2024-09-10 02:43

2024-09-10 02:43

Ceramic sintering has always been one of the core technologies in the heat treatment industry. With the advancement of industrial technology, the application range of ceramic sintering furnaces has continually expanded, and their importance in modern industry is increasingly prominent. This article will delve into the application cases of ceramic sintering furnaces in various industrial fields, as well as the technical advantages and practical effects they bring.

Principles of Ceramic Debinding and Sintering

In the ceramic manufacturing process, debinding and sintering are two critical steps that lay the foundation for the final performance and quality of the ceramic material. Below, we explain these two processes and their principles in detail.

Debinding Principle

Purpose and Function

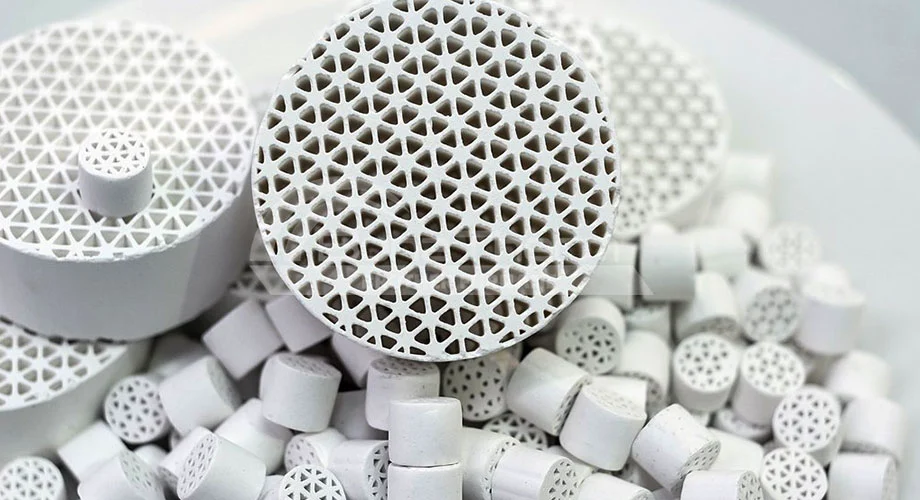

Debinding is an essential step before ceramic sintering, primarily aimed at removing organic components from the ceramic material, such as binders, plasticizers, and other additives. These organics are used in the initial preparation phase to improve the flowability and moldability of ceramic powders, but they may cause defects or affect the performance of the final product during high-temperature sintering.

Heating Process

The debinding process typically involves heating the ceramic samples to a lower temperature (usually below the sintering temperature of the ceramic). At this temperature range, organics begin to decompose. During heating, the organic additives in the ceramic decompose into gases such as water vapor and carbon dioxide, which then escape from the ceramic material.

Control Conditions

The debinding process requires precise control of the heating rate and atmosphere to ensure the thorough removal of organics while avoiding cracks in the ceramic material due to uneven heating. Typically, the atmosphere in the debinding furnace is controlled to be oxidizing or neutral to ensure complete combustion and removal of organics.

Sintering Principle

Purpose and Function

Sintering is the core step in the ceramic manufacturing process, aimed at heating the debound ceramic powder to high temperatures to cause bonding between the powder particles, forming a dense solid ceramic material. The sintering process determines the final properties of the ceramic material, such as strength, hardness, and stability.

High-Temperature Heating

During sintering, the ceramic samples are heated to their sintering temperature, which is usually above the melting point of the ceramic material but below its complete melting temperature. High-temperature heating causes solid diffusion between ceramic powder particles, gradually filling the gaps between particles and forming a solid structure.

Particle Bonding and Densification

As the temperature rises, the ceramic powder particles begin to bond together, forming strong connections. This process, known as densification, increases the material's density and mechanical strength. Temperature and atmosphere control during sintering are crucial for ensuring the uniformity and performance of the ceramic material.

Cooling Process

After sintering, the ceramic material needs to cool gradually to prevent cracking or deformation caused by sudden temperature drops. The cooling process also requires precise control to ensure the stability and quality of the final product.

Related Equipment for Ceramic Sintering

Ceramic sintering generally involves the use of lifting furnaces. Brother Furnace has extensive experience in the ceramic industry and has developed several types of equipment.

The most representative models include:

|  |

|  |

Additionally, if an atmosphere needs to be introduced, we also offer vacuum furnaces:

Vacuum Debinding and Sintering Furnace

Summary

The application of ceramic sintering furnaces in modern industry demonstrates their powerful ability to enhance product performance and production efficiency. With continuous technological advancements, the performance and application range of ceramic sintering furnaces will continue to expand, driving the development of industrial manufacturing technology.

If you are looking for furnaces for ceramic sintering, feel free to leave us a message, and Brother Furnace will provide you with the best solutions.