What is RTP Quick Cooling Tube Furnace

BROTHER FURNACE

BROTHER FURNACE

2025-01-08 22:33

2025-01-08 22:33

The RTP - Rapid Thermal Processing (RTP) Quick Cooling Tube Furnace is a high-performance tube furnace designed to combine rapid thermal processing with fast cooling capabilities. This equipment is primarily used in semiconductor, materials science, and new energy industries to achieve rapid heating and cooling of samples, with temperatures reaching up to 1200°C. This article will provide a detailed overview of the working principles, features, and key applications of the RTP Quick Cooling Tube Furnace.

Working Principle of RTP - Quick Cooling Tube Furnace

The RTP Quick Cooling Tube Furnace rapidly heats and cools samples through precise control of energy sources and cooling techniques. It utilizes forced gas cooling or water-cooling technology to perform temperature changes in an extremely short amount of time.

Heating Stage

The RTP tube furnace rapidly heats samples using a powerful resistive heating system. The heating process is fast, allowing the furnace to reach high temperatures in a short period, typically within seconds to minutes.

Rapid Cooling

After heating, the furnace uses gases such as nitrogen or argon to cool the samples quickly. The fast cooling rate allows the temperature to drop rapidly, which is critical for controlling the crystal structure or surface properties of materials.

Atmosphere Control

The RTP tube furnace can operate in a precisely controlled atmosphere. The choice of atmosphere, such as oxygen, nitrogen, or vacuum, significantly affects the results of the processing, making atmosphere control a crucial factor for processing different materials.

Common Applications of RTP Quick Cooling Tube Furnace

RTP Quick Cooling Tube Furnaces are used in experiments and industrial processes requiring rapid heating and cooling. They are particularly common in materials science, semiconductor manufacturing, and other high-tech sectors. Some typical applications include:

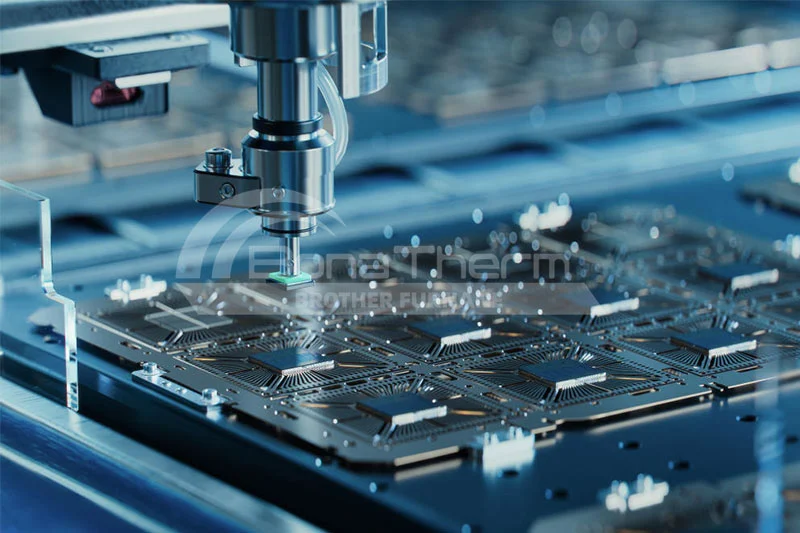

Semiconductor Manufacturing

Thin Film Deposition and Annealing: RTP furnaces are extensively used for thin film deposition, annealing, and other heat treatments in semiconductor manufacturing. Rapid heating and cooling are essential, especially during silicon wafer annealing, as they effectively control crystal structure and enhance material properties.

Rapid Thermal Annealing (RTA)

With precise temperature control, RTP furnaces enable rapid thermal annealing, crucial for improving the performance and quality of semiconductor devices.

Materials Research and Development

Rapid Heating and Cooling of Thin Films: In materials research, particularly for metals, ceramics, or composites, RTP's ability to rapidly heat and cool helps researchers quickly observe how materials behave under different temperature conditions.

Rapid Heat Treatment (RTP) allows for rapid transitions through high-temperature stages followed by fast cooling, achieving desired physical and chemical properties for high-temperature alloys and other materials.

High-Precision Experimental Needs

Thermal Cycling Experiments: RTP furnaces provide precisely controlled rapid heating and cooling processes, making them ideal for thermal cycling experiments in research labs to study the effects of thermal stress on materials.

Temperature-Sensitive Material Processing: For materials that are sensitive to temperature variations, the rapid cooling feature of RTP furnaces helps prevent overheating and material degradation.

Optoelectronics and Solar Cell Manufacturing

RTP is used for processing thin films, epitaxial growth, and annealing in the production of optoelectronic devices and solar cells. These processes require high-precision temperature control and fast cooling to achieve optimal electrical and optical properties.

Heat Treatment of Glass, Ceramics, and Other High-Temperature Materials:

RTP furnaces are also used for heat treatment of certain types of glass, ceramics, and high-temperature materials, where rapid thermal cycling enhances hardness, wear resistance, or other physical properties.

Metal Welding and Hardening:

In metal welding and surface hardening applications, rapid cooling helps improve metal strength and hardness while preventing unwanted microstructural changes during cooling.

Conclusion

Brother Furnace provides RTP - Rapid Thermal Processing Quick Cooling Tube Furnaces for global clients. With capabilities for rapid heating and cooling, excellent temperature uniformity, and support for various atmospheres, RTP furnaces have become essential tools in semiconductor, materials science, and new energy industries. If you are looking for high-performance thermal processing equipment, the RTP Quick Cooling Tube Furnace is an ideal choice.

For more technical information or to request a solution, please feel free to contact us!