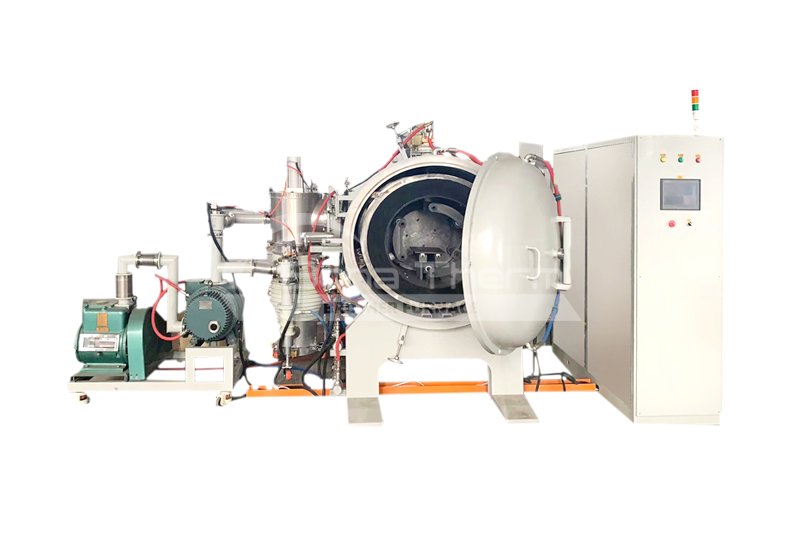

Introduction of Vacuum Tungsten Furnace

The vacuum tungsten furnace is a high-temperature heat treatment device that utilizes tungsten filaments as heating elements, specifically designed for precise material processing in a vacuum environment. Due to its exceptionally high melting point and excellent thermal stability, tungsten can perform reliably at extreme temperatures, typically achieving operating temperatures of over 2000°C. During heating, the vacuum system maintains a low-pressure environment, effectively reducing oxidation and impurities, which enhances material purity and ensures consistent quality.

|  |

Features of Vacuum Tungsten Furnace

High-Temperature Heating System

The vacuum tungsten filament furnace is equipped with a specially designed tungsten mesh heater and tungsten foil heat shield, achieving a maximum temperature of 2400°C to meet extremely high-temperature processing requirements.

Advanced Vacuum System

The furnace includes direct-connected vacuum pumps and molecular pumps, reaching an ultimate vacuum level of 6x10⁻⁴ Pa, providing an oxygen-free environment for high-purity material processing.

Intelligent Human-Machine Interface

A high-definition touchscreen interface with a proprietary operating system developed by our company offers intuitive and efficient control.

Multi-Gas Support

The furnace can be filled with various gases, including nitrogen, argon, hydrogen, and nitrogen-hydrogen mixtures, offering flexibility to meet diverse processing needs.

Optional Accessories

- Chiller

- Tungsten crucible

Applications of Vacuum Tungsten Furnace

The vacuum tungsten filament furnace is widely used in the semiconductor, aerospace, electronics, metal smelting, and ceramic materials industries, and is commonly applied in the following processes:· High-Temperature Sintering: Used for sintering advanced ceramics and powder metals, enhancing material density and strength.

· Heat Treatment: Suitable for quenching, annealing, and tempering, especially for refractory metals.

· Evaporation Coating: In semiconductor and optical component manufacturing, the tungsten filament heats and evaporates materials for deposition onto target surfaces.

· Vacuum Annealing: Provides a non-oxidizing environment for annealing metal parts, reducing surface oxidation and improving material properties.

Technical Parameter

Model | Heating Zone (Dia * Height) | Temperature | Temp. Uniformity | Power | Vacuum |

|---|---|---|---|---|---|

BR-WSL-1010 |

ф100x 100mm |

1900℃ |

±3℃ |

21KW |

6x10-5Pa |

BR-WSL-2030 |

ф200x300mm |

1900℃ |

±3℃ |

68KW |

6x10-5Pa |

BR-WSL-3050 |

ф300x500mm |

1900℃ |

±3℃ |

120KW |

6x10-5Pa |

BR-WSL-4060 |

ф400x600mm |

1900℃ |

±3℃ |

160KW |

6x10-5Pa |