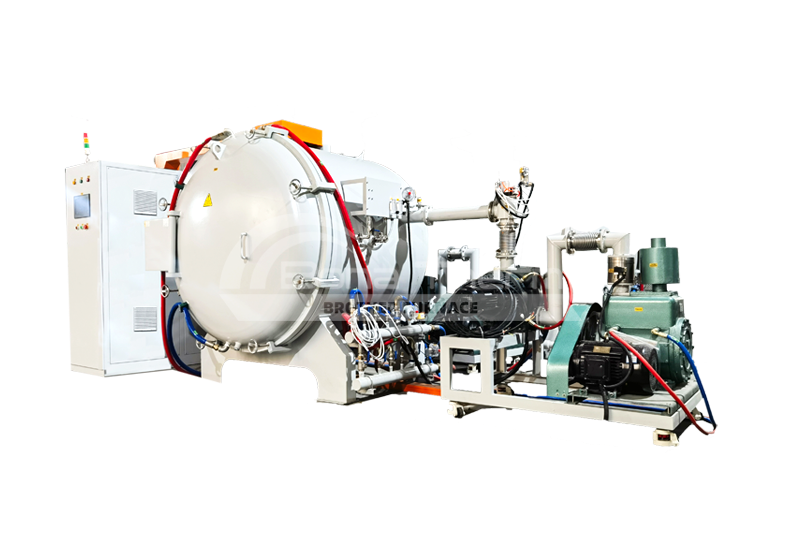

Introduction of Vacuum Molybdenum Furnace

The Vacuum Sintering Furnace from Brother Furnace operates at temperatures up to 1350°C in a vacuum environment, effectively preventing oxidation or contamination of the samples. The furnace utilizes molybdenum strips as heating elements, delivering uniform and efficient heating performance. This equipment is particularly suitable for the sintering of ceramics, metals(silver/copper/nickel base as flux), and composite materials, enabling the processing of complex shapes and high-precision components. Owing to its high vacuum capability, the vacuum sintering furnace ensures that samples maintain a stable chemical environment throughout the process, enhancing the final product's density and mechanical properties. It is widely used in the fields of aerospace, electronics, and new materials.

Advantages of Vacuum Molybdenum Furnace

- The vacuum sintering furnace uses a molybdenum foil metal furnace and molybdenum heating belt as heating elements, the maximum temperature can reach 2000℃.

- The molybdenum heating belt is distributed annularly in the furnace and is heated by radiation all around. The furnace temperature has high uniformity and can reach plus or minus 5 degrees Celsius.

- Clean metal molybdenum furnace, equipped with mechanical pump + diffusion pump vacuum unit (optional molecular pump unit), the ultimate vacuum degree can reach 7x10-3pa (no load, cold state).

- The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

- PLC automatic control system.

- If necessary, inert gas can be filled to accelerate cooling.

Accessories of Vacuum Molybdenum Furnace

- External rapid cooling system; from brazing temperature to 180 degrees in less than 1 hour.

- The multi-layer material rack made of high-purity molybdenum is convenient for placing multi-layer brazing workpieces.

- Chiller

- High-quality flux imported from the United States.

|  |

Benefits of Using the Brother Furnace Vacuum Molybdenum Foil Furnace

Oxidation and Contamination Prevention: The vacuum sintering process effectively prevents the oxidation of the material surface and the deposition of other impurities, ensuring high purity and quality of the products.

High-Temperature Performance: Molybdenum foil, as a heating element, maintains excellent stability, oxidation resistance, and high purity at elevated temperatures, allowing for precise control of the temperature within the furnace, which is essential for complex sintering processes.

Enhanced Density: Under vacuum conditions, the density of the materials is improved, effectively eliminating bubbles and defects during the sintering process, thus enhancing the mechanical strength and durability of the final products.

Wide Material Compatibility: The vacuum furnace is compatible with a variety of materials, including advanced ceramics, metals, and composite materials, catering to diverse industrial needs.

Energy Efficiency: The design of the molybdenum foil furnace features efficient thermal conductivity, enabling it to reach the required sintering temperature in a shorter time, which reduces energy consumption and production time.

Precise Process Control: With accurate control over vacuum conditions and temperature, the sintering process can be optimized, increasing production efficiency and ensuring product consistency and repeatability.

Versatility: In addition to sintering, this furnace can also be utilized for heat treatment and other high-temperature experiments, such as brazing and quenching, thereby broadening its application range.

Technical Parameters of Vacuum Molybdenum Furnace

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHM-223 | 200*200*300 | 1350 | 34 | 380 |

BR-QHM-334 | 300*300*400 | 1350 | 60 | 380 |

BR-QHM-446 | 400*400*600 | 1350 | 98 | 380 |

BR-QHM-557 | 500*500*700 | 1350 | 132 | 380 |

BR-QHM-669 | 600*600*900 | 1350 | 180 | 380 |