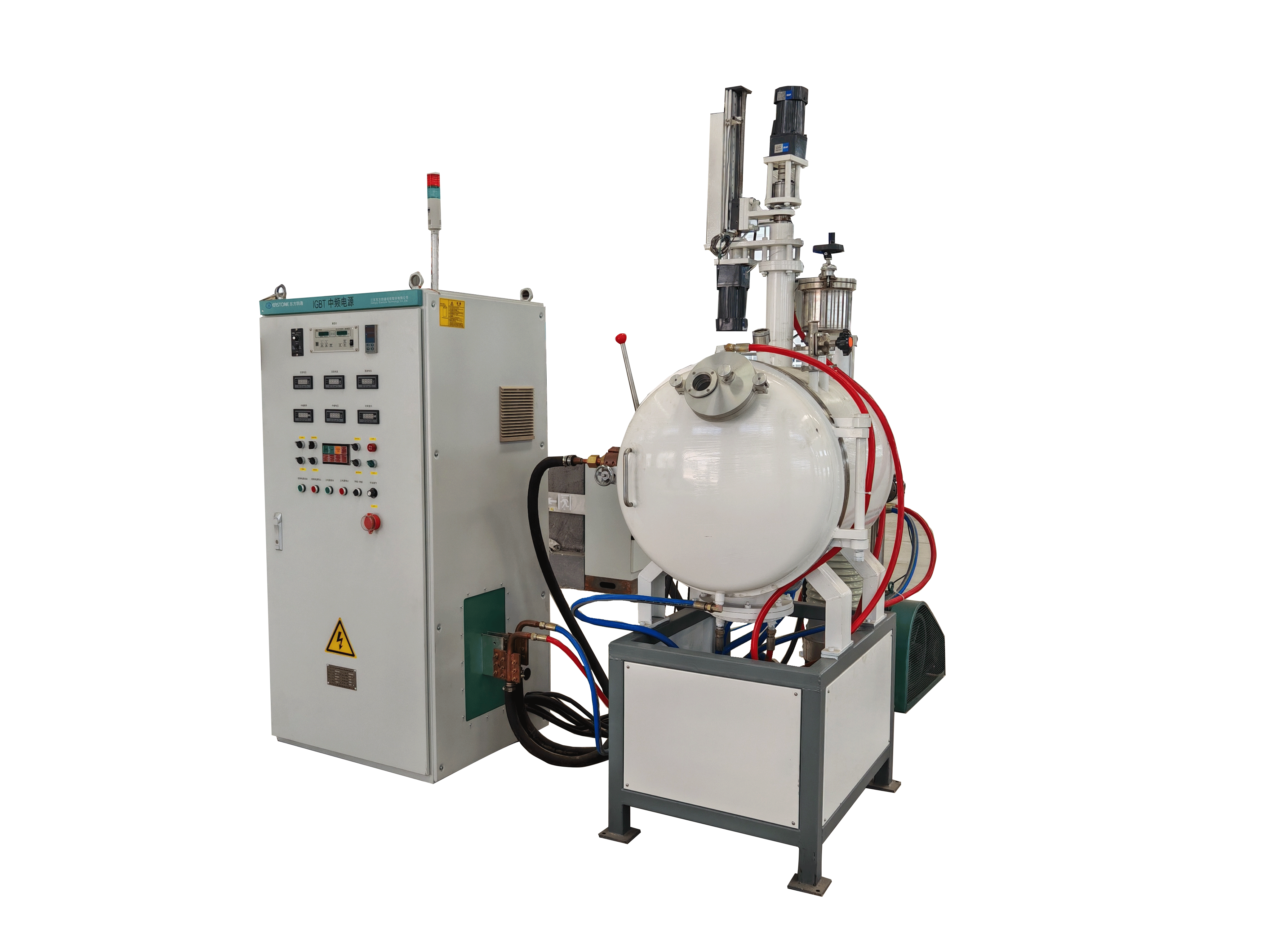

Introduction of Vacuum Induction Melting Furnace

The vacuum induction melting furnace operates on the principle of medium-frequency induction heating and is equipped with a high-vacuum system. This setup allows for the melting of metals under high-vacuum conditions. The furnace is widely used to research and produce nickel-based and specialty steels, precision alloys, reactive metals, high-temperature alloys, and magnetic materials. It is also suitable for the precision casting of small components under vacuum.

|  |

Features of Brother Furnace's Vacuum Induction Melting Furnace

1. High Temperature and Efficiency: The furnace uses IGBT or KGPS medium-frequency power supplies, achieving temperatures up to 2300°C. This high-temperature range facilitates the melting of a variety of metals and alloys.

2. Advanced Vacuum System: Equipped with a mechanical pump, roots pump, and diffusion pump, the furnace achieves an ultimate vacuum of up to 6x10⁻³ Pa. This ensures a clean melting environment with minimal contamination.

3. Versatile Feeding Options: Standard alloy feeders allow for the sequential addition of materials into the crucible. An optional secondary feeding system enables continuous addition of elements in a vacuum environment, enhancing flexibility in sample preparation.

4. User-Friendly Interface: The furnace features a high-definition touchscreen interface with a custom-developed operating system and a PLC automatic control system for precise melting process management.

5. Observation and Maintenance: The furnace includes a viewing window on the lid for monitoring internal conditions. The window is covered with a shield to prevent contamination from metal vapors.

6. Modular and Convenient Design: The induction coil inside the furnace is made from rectangular copper tubes and is mounted on electrodes for easy assembly and disassembly. Pre-sintered crucibles can be placed inside the coil, or crucibles can be molded directly in the coil.

Applications of Vacuum Induction Melting Furnace

High-Temperature and High-Purity Metal Production:

The furnace is used to produce high-melting-point metals and alloys, such as nickel-based alloys, titanium alloys, and other specialty materials. It is particularly valuable in applications requiring high purity and precise control.

Research and Development:

It is an essential tool for research institutions and universities for the study and development of new materials and alloys under controlled vacuum conditions.

Precision Casting:

The furnace supports the precision casting of small components, making it ideal for industries that require high-quality, defect-free castings.

Flexible Use in Various Atmospheres:

The furnace can operate under different atmospheres, including air, protective gases, and upgraded high-vacuum conditions. This versatility makes it suitable for a range of metallurgical and casting applications.

High-Purity Metal and Alloy Production:

The vacuum induction melting furnace is well-suited for producing high-purity or highly reactive metals, as the vacuum environment minimizes contamination and oxidation during the melting process.

Technical Parameters

Laboratory vacuum induction melting furnace

model | Temperature (℃) | Power (kW) | Ultimate vacuum degree | Capacity ( kg ) |

|---|---|---|---|---|

BR- KZG-3 | 0-1750 | 35 | 5*10-3pa | 5 |

BR- KZG-5 | 0-1750 | 45 | 5*10-3pa | 5 |

BR- KZG-10 | 0-1750 | 65 | 6.7*10-3pa | 10 |

BR- KZG-25 | 0-1750 | 100 | 6.7*10-3pa | 25 |

BR- KZG-50 | 0-1750 | 160 | 6.7*10-3pa | 50 |

BR- KZG-100 | 0-1750 | 200 | 6.7*10-3pa | 100 |

Industrial production vacuum induction melting furnace

model | Loading capacity (kgs) | Rated frequency (Hz) | Rated power (kW) | Ultimate vacuum degree | Cooling water consumption ( t/h ) |

|---|---|---|---|---|---|

BR-RLL-10 | 10 | 3000 | 60 | 6x10-3Pa | 10 |

BR-RLL-25 | 25 | 2500 | 120 | 6x10-3Pa | 15 |

BR-RLL-50 | 50 | 2000 | 160 | 6x10-3Pa | 25 |

BR-RLL-100 | 100 | 2000 | 200 | 6x10-3Pa | 30 |

BR-RLL-200 | 200 | 1000 | 200 | 6x10-3Pa | 35 |

BR-RLL-300 | 300 | 800 | 250 | 6x10-3Pa | 40 |

BR-RLL-500 | 500 | 800 | 350 | 6x10-3Pa | 50 |

BR-RLL-1000 | 1000 | 800 | 400 | 6x10-3Pa | 70 |

Get Inquiry

Get Inquiry Send Email

Send Email