Introduction

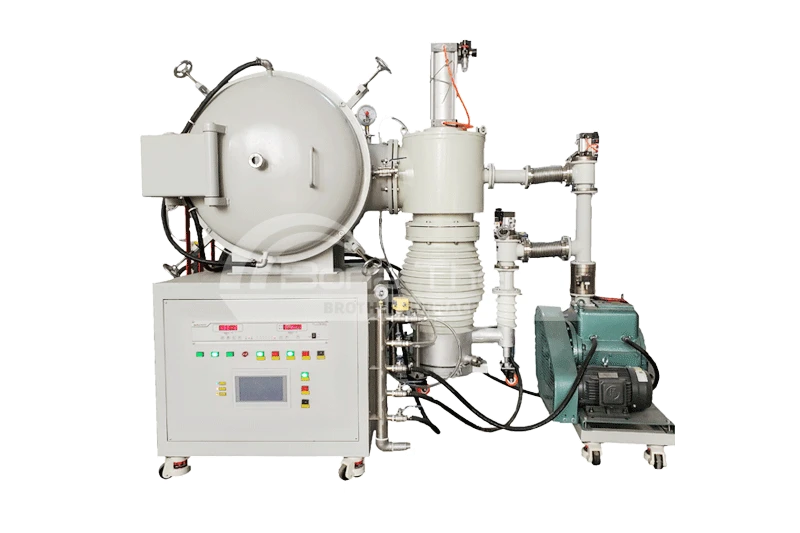

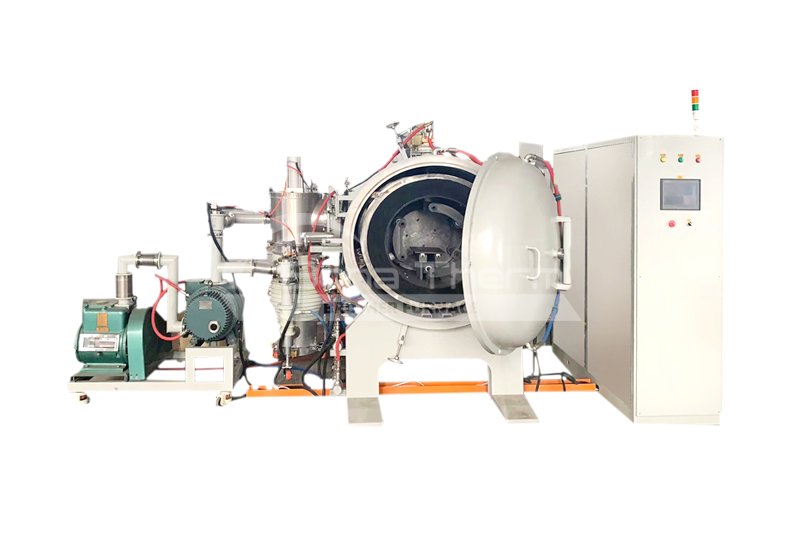

The ceramic fiber thermal field vacuum heat treatment furnace is a very cost-effective vacuum furnace. Low price, simple operation, excellent vacuum effect, and good temperature field uniformity. It is used in high-temperature vacuum sintering, annealing, and tempering of ceramic materials, ceramic metal composite materials, refractory metals, and alloy materials.

Features

The ultimate vacuum degree can reach 10Pa (two-stage rotary vane vacuum pump) or 7x10-2Pa (two-stage rotary vane vacuum pump + diffusion pump).

The maximum temperature is 1200℃ or 1700℃ optional.

Designed with an air inlet and exhaust port, it can be used for vacuuming or filled with inert gas.

Pneumatic vacuum valve is easy and convenient to operate.

It uses an alumina ceramic fiber furnace and resistance wire or silicon molybdenum rod for heating. While ensuring excellent use effects, the cost of the electric furnace is greatly reduced.

Double-layer water cooling, furnace shell surface temperature ≤50℃.

Made of high-strength carbon steel, the exterior is electrostatically sprayed, beautiful, and elegant.

The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

Programmable temperature control instrument PID adjustment.

Upper limit alarm, deviation alarm, automatic stop after program running, no need for human supervision.

Optional Accessories

Independent control cabinet

PLC automatic control system

Chiller

Furnace rapid cooling system

Technical Parameters

1700 type vacuum heat treatment furnace parameters

model | Maximum temperature(℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-12VF-1 | 1200 | 1100 | 100*100*100 | Resistance wire | 1 | 1.2 | 10Pa |

BR-12VF-5 | 1200 | 1100 | 150*150*200 | Resistance wire | 4.5 | 3.5 | 10Pa |

BR-12VF-12 | 1200 | 1100 | 200*200*300 | Resistance wire | 12 | 5 | 10Pa |

BR-12VF-36 | 1200 | 1100 | 300*300*400 | Resistance wire | 36 | 12 | 10Pa |

BR-12VF- 96 | 1200 | 1100 | 400*400* 6 00 | Resistance wire | 80 | 18 | 10Pa |

BR-12VF-1 7 5 | 1200 | 1100 | 500*500*700 | Resistance wire | 175 | 30 | 10Pa |

BR-12VF- 324 | 1200 | 1100 | 600*600*900 | Resistance wire | 324 | 50 | 10Pa |

BR-12VF- 768 | 1200 | 1100 | 800*800*1200 | Resistance wire | 768 | 80 | 10Pa |

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-12 H VF-1 | 1200 | 1100 | 100*100*100 | Resistance wire | 1 | 1.2 | 7x10-2Pa |

BR-12HVF-5 | 1200 | 1100 | 150*150*200 | Resistance wire | 4.5 | 3.5 | 7x10-2Pa |

BR-12HVF-12 | 1200 | 1100 | 200*200*300 | Resistance wire | 12 | 5 | 7x10-2Pa |

BR-12HVF-36 | 1200 | 1100 | 300*300*400 | Resistance wire | 36 | 12 | 7x10-2Pa |

BR-12HVF- 96 | 1200 | 1100 | 400*400* 6 00 | Resistance wire | 80 | 18 | 7x10-2Pa |

BR-12 H VF-1 7 5 | 1200 | 1100 | 500*500*700 | Resistance wire | 175 | 30 | 7x10-2Pa |

BR-12H VF - 324 | 1200 | 1100 | 600*600*900 | Resistance wire | 324 | 50 | 7x10-2Pa |

BR-12H VF - 768 | 1200 | 1100 | 800*800*1200 | Resistance wire | 768 | 80 | 7x10-2Pa |

1700 type vacuum heat treatment furnace parameters

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-17VF-1 | 1700 | 1600 | 100*100*100 | Silicon molybdenum rod | 1 | 1.5 | 10Pa |

BR-17VF-5 | 1700 | 1600 | 150*150*200 | Silicon molybdenum rod | 4.5 | 5 | 10Pa |

BR-17VF-12 | 1700 | 1600 | 200*200*300 | Silicon molybdenum rod | 12 | 8 | 10Pa |

BR-17VF-36 | 1700 | 1600 | 300*300*400 | Silicon molybdenum rod | 36 | 12 | 10Pa |

BR-17VF- 96 | 1700 | 1600 | 400*400*500 | Silicon molybdenum rod | 80 | 30 | 10Pa |

BR-17VF-1 7 5 | 1700 | 1600 | 500*500*700 | Silicon molybdenum rod | 175 | 45 | 10Pa |

BR-17VF- 324 | 1700 | 1600 | 600*600*900 | Silicon molybdenum rod | 324 | 66 | 10Pa |

BR-17VF- 768 | 1700 | 1700 | 800*800*1200 | Silicon molybdenum rod | 768 | 120 | 10Pa |

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-17H VF -1 | 1700 | 1600 | 100*100*100 | Silicon molybdenum rod | 1 | 1.5 | 7x10-2Pa |

BR-17HVF-5 | 1700 | 1600 | 150*150*200 | Silicon molybdenum rod | 4.5 | 5 | 7x10-2Pa |

BR-17HVF-12 | 1700 | 1600 | 200*200*300 | Silicon molybdenum rod | 12 | 8 | 7x10-2Pa _ |

BR-17HVF-36 | 1700 | 1600 | 300*300*400 | Silicon molybdenum rod | 36 | 12 | 7x10-2Pa |

BR-17HVF- 96 | 1700 | 1600 | 400*400*500 | Silicon molybdenum rod | 80 | 30 | 7x10-2Pa |

BR-17HVF-1 7 5 | 1700 | 1600 | 500*500*700 | Silicon molybdenum rod | 175 | 45 | 7x10-2Pa |

BR-17HVF- 324 | 1700 | 1600 | 600*600*900 | Silicon molybdenum rod | 324 | 66 | 7x10-2Pa |

BR-17H VF - 768 | 1700 | 1700 | 800*800*1200 | Silicon molybdenum rod | 768 | 120 | 7x10-2Pa |