Introduction

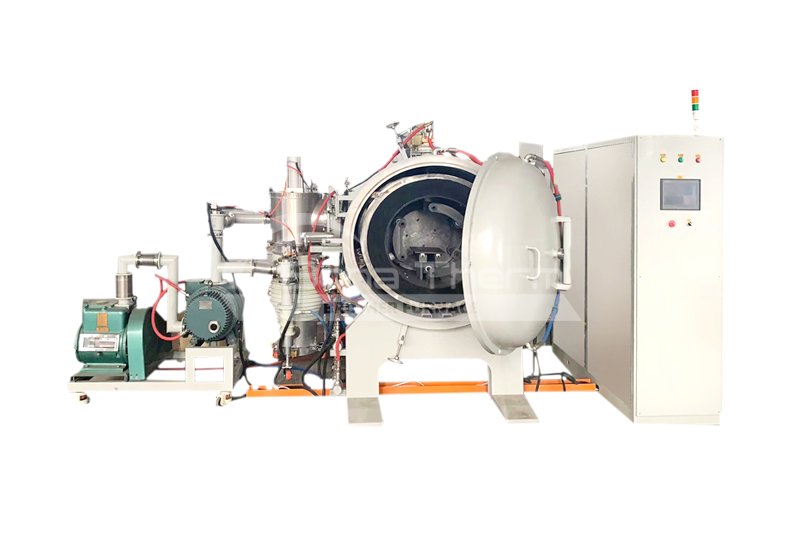

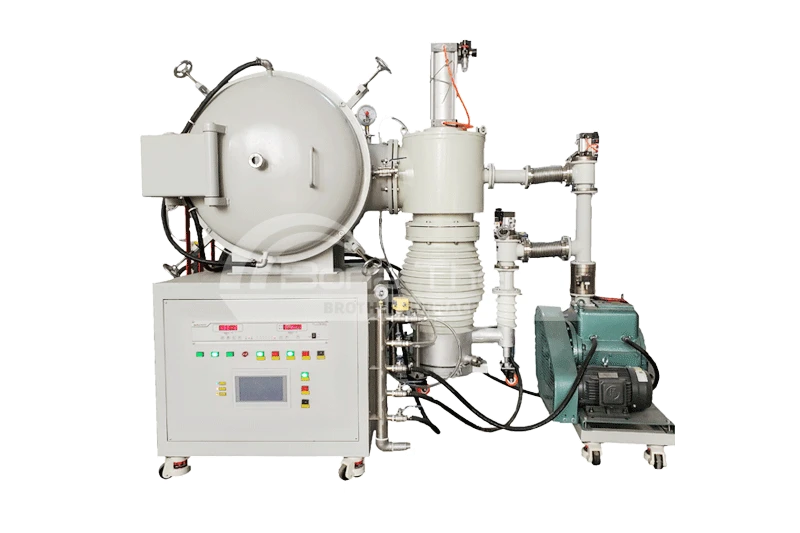

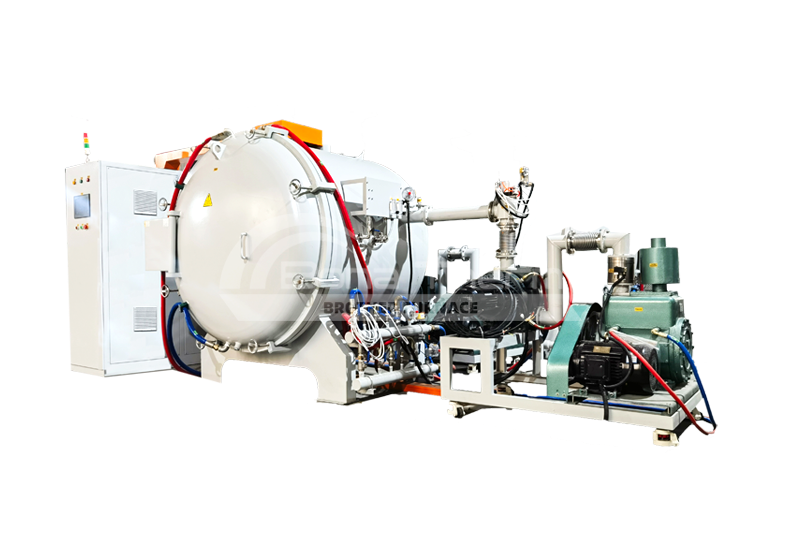

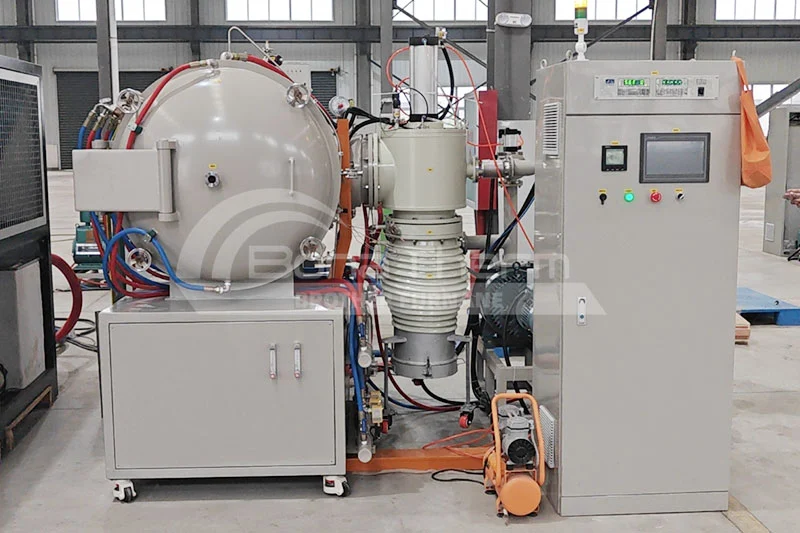

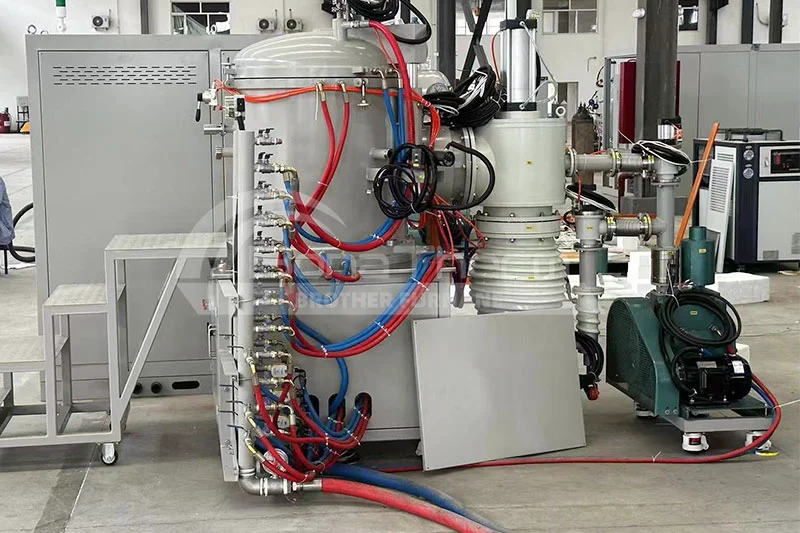

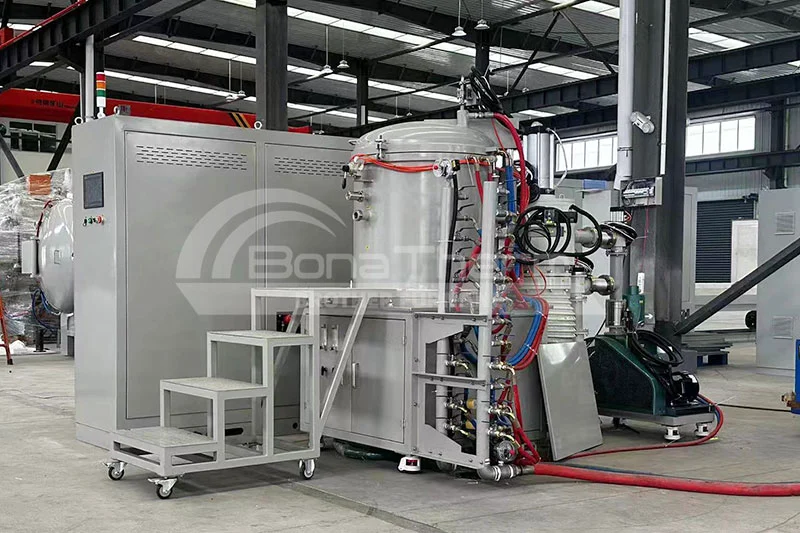

Vacuum vertical graphite carbon tube furnace is periodic working and adopts graphite tubes as heating elements, the working chamber is round and vertical, mainly used for sintering metal material, and non-metal material in a vacuum or protective atmosphere environment, and can also be used for sintering and purification of optical material.

Features

- Using graphite as the heating element, the maximum working temperature can reach 2400°C.

- The inner layer of the furnace shell is made of polished stainless steel, and the outer layer is made of carbon steel, with a double-layer water-cooled structure.

- There is an observation window on the furnace shell to facilitate observation of the heating conditions in the furnace.

- The human-machine interface adopts a high-definition touchscreen and has a built-in operating system developed by our company.

- PLC automatic control system.

- Use a tungsten-rhenium thermocouple and an infrared thermometer to measure temperature. The tungsten-rhenium thermocouple can enter and exit automatically.

Optional Accessories

- Chiller

- Graphite crucible

Applications

● Material Heat Treatment:

The vacuum graphite carbon tube furnace can be used for high-temperature heat treatment of materials, such as metal alloys, ceramics, and other substances. Conducting heat treatment in a vacuum environment helps avoid the influence of oxygen and other gases on the material, resulting in purer outcomes.

● Laboratory Research:

Research institutions and laboratories can utilize this furnace for various experiments, including the study of material properties, crystal growth, and other high-temperature experiments.

● Chemical Vapor Deposition (CVD):

The vacuum graphite carbon tube furnace can also be employed in chemical vapor deposition processes, where gases are used to deposit thin films on a substrate to prepare functional materials.

● Carbon Nanotube Synthesis:

Due to the sensitivity of carbon nanotubes to high-temperature and vacuum conditions, this furnace can be used for the preparation and research of carbon nanotubes.

● Crystal Growth:

High-temperature treatments in a vacuum environment aid in controlling the conditions for crystal growth, crucial for the preparation of semiconductors and other materials.

● Pyrolysis and Annealing:

The equipment can be used for pyrolysis and annealing processes, essential for improving the crystalline structure and performance of materials.

● Graphene Synthesis:

The Vacuum Graphite Carbon Tube Furnace can also be employed in the preparation of graphene, where a carbon source is heated to generate graphene layers.

Technical Parameters

model | Studio size (diameter*height) ( mm ) | Working temperature (℃) | Power (kW) | Power supply ( V ) | Ultimate vacuum degree |

|---|---|---|---|---|---|

BR- 18 STV-40 | Φ1 6 0×160 | 1800 | 35 | 380 | 6.67×10-3Pa |

BR- 18 STV- 5 0 | Φ 20 0 × 30 0 | 1800 | 60 | 380 | |

BR-22STV-40 | Φ1 6 0×160 | 2200 | 50 | 380 | |

BR-22STV-50 | Φ 20 0 × 30 0 | 2200 | 90 | 380 |

Get Inquiry

Get Inquiry Send Email

Send Email