Introduction

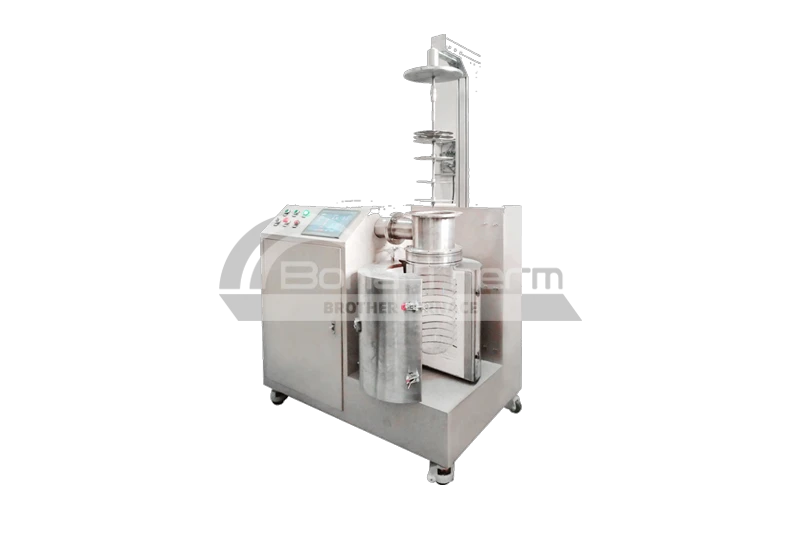

BR-200BF series brazing furnace is widely used in the welding of various smaller-sized superhard materials, mainly used for carbide cutting tools (PCD cutting tools, PCBN cutting tools, CVD cutting tools, CBN cutting tools, engraving knives, etc.), drilling drill bits, stainless steel Brazing, single crystal welding, porcelain metal brazing, heterogeneous metal components, complex thin plates: sandwich components, honeycomb structures, etc.

|  |  |

|  |  |

Features

- Full PLC control, manual control can also be switched, 10-inch high-definition touch screen, 50-segment programming, 30-segment program storage, simple operation, and continuous production.

- Temperature curves and vacuum curves can be exported.

- The surface of the welding workpiece is clean and beautiful, environmentally friendly, and non-oxidizing; the double-layer stainless steel material table allows welding materials to be placed in large quantities and neatly.

- Using ring and bottom heating, the welding strength is high, which is 2-3 times that of ordinary high-frequency welding.

- With high production capacity, the number of single welding can reach more than 600 pieces (taking CNGA1204 as an example).

- Provide technology and 20 years of experience and technical support to ensure the production of high-quality products.

- The vacuum system consists of a direct-coupled pump and a diffusion pump, and the ultimate vacuum degree can reach 7x10-3pa (no load, cold state).

Optional accessories

Chiller; Vacuum oven; Ultrasonic cleaning machine; Flux solder paste;

Brazing process

Ultrasonic cleaning →daub solder paste→vacuum drying→vacuum brazing.

Technical Parameters

Model | Max Temp. (℃) | Chamber size(mm) | Overall size(mm) | Power (kW) | Thermocouple |

|---|---|---|---|---|---|

BR-200BF | 1200 | 200x400 | 1235x1150x750 | 8 | K Type |