The Process and Benefits of Vacuum Brazing Copper and Stainless Steel

BROTHER FURNACE

BROTHER FURNACE

2024-10-10 19:52

2024-10-10 19:52

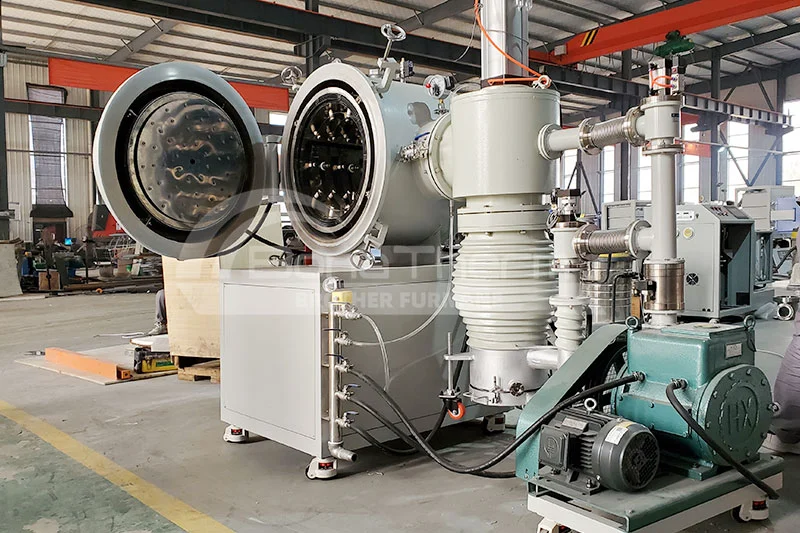

Vacuum brazing is an essential technique for creating high-strength joints between different metals, such as copper and stainless steel. This method is especially valued in industries requiring clean, durable, and corrosion-resistant bonds. A vacuum furnace or brazing furnace is typically used to ensure a precise, oxidation-free environment that enhances the quality of the brazed joint.

What Is Vacuum Brazing?

Vacuum brazing involves heating metals in a controlled vacuum environment, using a filler metal (often copper) to form a strong bond between components. This process is particularly effective for joining copper and stainless steel, two metals with different physical properties. The vacuum brazing furnace heats the materials to just below their melting points, allowing the copper filler to flow and create a robust joint without distorting the base metals.

Why Vacuum Brazing is Ideal for Copper and Stainless Steel

· Oxidation Prevention: The vacuum environment eliminates oxygen and other gases that could cause oxidation or contamination on the surfaces of the metals. This is critical when working with metals like copper and stainless steel, ensuring a clean, high-quality joint.

· Precise Temperature Control: Copper and stainless steel have different thermal properties, so precise temperature control is essential. The vacuum furnace provides accurate temperature management, reducing the risk of overheating and thermal stress.

· Strength and Durability: Vacuum brazing produces strong joints that can withstand mechanical stress, temperature fluctuations, and corrosion, making it ideal for demanding industrial applications.

Key Benefits of Using a Vacuum Furnace

· Uniform Heating: The vacuum furnace ensures even heat distribution, which is crucial when brazing metals with different melting points. This leads to consistent results and high-quality joints.

· Minimal Post-Processing: Due to the clean brazing environment, components often require little to no post-processing, such as cleaning or finishing.

· Efficient Process: Vacuum brazing is an efficient process, reducing production time while maintaining the highest quality standards for copper-stainless steel joints.

Applications of Vacuum Brazing Copper and Stainless Steel

Vacuum brazing is commonly used in industries such as:

· HVAC Systems: Where copper’s excellent thermal conductivity and stainless steel’s strength and corrosion resistance are needed for heat exchangers and other components.

· Aerospace and Automotive: These industries require durable, high-performance materials that can withstand extreme conditions. Vacuum-brazed copper-stainless steel joints are ideal for components like fuel systems, heat exchangers, and engine parts.

· Electronics: Electrical systems often require reliable, corrosion-resistant joints that ensure efficient conductivity. Vacuum brazing provides these benefits, making it perfect for copper and stainless steel connections.

Conclusion

Vacuum brazing of copper and stainless steel is a proven process that creates high-strength, oxidation-free, thermally efficient joints. Brother Furnace has many successful cases of vacuum brazing and welcomes inquiries from customers around the world about our vacuum furnace equipment.