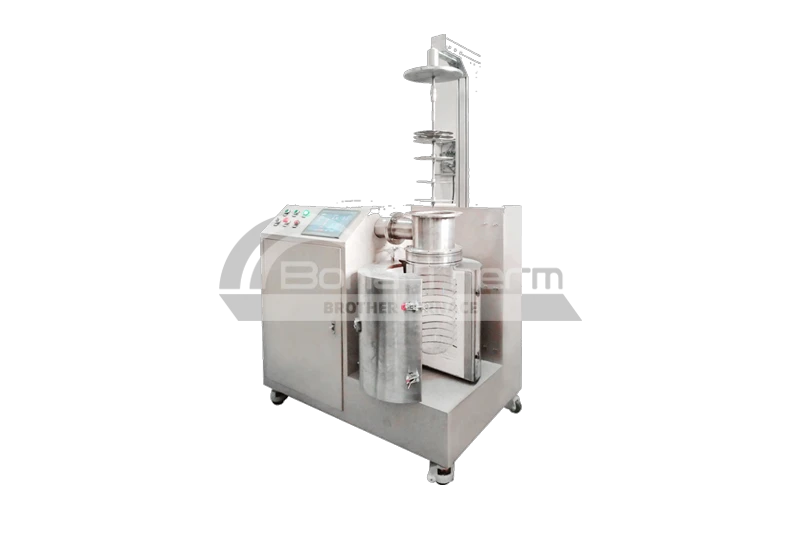

Introduction of Vacuum Aluminum Brazing Furnace

Our vacuum brazing furnace is specially designed for the precision brazing of aluminum components. Featuring advanced temperature control and a high-vacuum environment, this furnace ensures superior brazing quality by minimizing oxidation and impurities. Whether used in aerospace, automotive, or electronics industries, our vacuum brazing furnace guarantees high-strength, corrosion-resistant joints. Maximum brazing temperature up to 1500℃.

Advantages of the Vacuum Aluminum Brazing Furnace

High-Precision Temperature Control: Equipped with advanced temperature sensors and controllers, the furnace ensures precise heating, critical for aluminum brazing where tight tolerances are required.

Oxidation-Free Environment: The high-vacuum atmosphere minimizes oxidation, resulting in cleaner and stronger brazed joints with no need for flux.

Energy-Efficient Design: Our vacuum brazing furnace is engineered for optimal energy efficiency, reducing operational costs while maintaining high performance.

Uniform Heating: With a sophisticated heating system, the furnace guarantees uniform temperature distribution, preventing any thermal distortion or defects in the aluminum workpieces.

Flexible Batch Processing: The furnace accommodates both small and large batches, making it ideal for a wide range of production volumes.

Applications of the Vacuum Aluminum Brazing Furnace

Aerospace Industry: Used for manufacturing critical components such as heat exchangers, radiators, and structural parts that require high-strength joints.

Automotive Industry: Ideal for brazing aluminum components like fuel tanks, heat sinks, and radiators, ensuring lightweight and durable parts for modern vehicles.

Electronics Industry: Ensures reliable bonding of aluminum heat sinks, circuit boards, and other delicate electronic components where thermal management is crucial.

HVAC Systems: The vacuum brazing furnace is perfect for brazing aluminum components in heating, ventilation, and air conditioning systems, contributing to efficient heat transfer and durable constructions.

|  |

Why Choose Brother Furnace Vacuum Aluminum Brazing Furnace?

Customizable to Your Needs: We offer customization options, including chamber size, heating capacity, and automation features, to meet the specific requirements of your production process.

Proven Expertise: With years of experience in vacuum furnace manufacturing, our equipment is trusted by leading companies worldwide for its reliability and performance.

Technical Support and Service: Our team provides comprehensive after-sales support, ensuring that your furnace operates at peak efficiency throughout its lifetime.

Technical Parameters

heat-resistant steel hot field

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHS-223 | 200*200*300 | 750 | 12 | 380 |

BR-QHS-334 | 300*300*400 | 750 | twenty one | 380 |

BR-QHS-446 | 400*400*600 | 750 | 34 | 380 |

BR-QHS-557 | 500*500*700 | 750 | 46 | 380 |

BR-QHS-669 | 600*600*900 | 750 | 64 | 380 |

molybdenum thermal field

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHM-223 | 200*200*300 | 1350 | 34 | 380 |

BR-QHM-334 | 300*300*400 | 1350 | 60 | 380 |

BR-QHM-446 | 400*400*600 | 1350 | 98 | 380 |

BR-QHM-557 | 500*500*700 | 1350 | 132 | 380 |

BR-QHM-669 | 600*600*900 | 1350 | 180 | 380 |