Introduction of Rotary Tube Furnace

The rotary tube furnace is specially designed to obtain better consistency when sintering inorganic compounds. It is especially suitable for preparing negative electrode materials with conductive coatings for lithium-ion batteries; it can also be used for uniform drying and calcination of materials. The furnace body can be tilted 30 degrees and the furnace tube can be rotated 360 degrees. According to needs, it can also be made into dual temperature zones.

|  |  |

|  |  |

Features

● Max temperature 1200 ℃

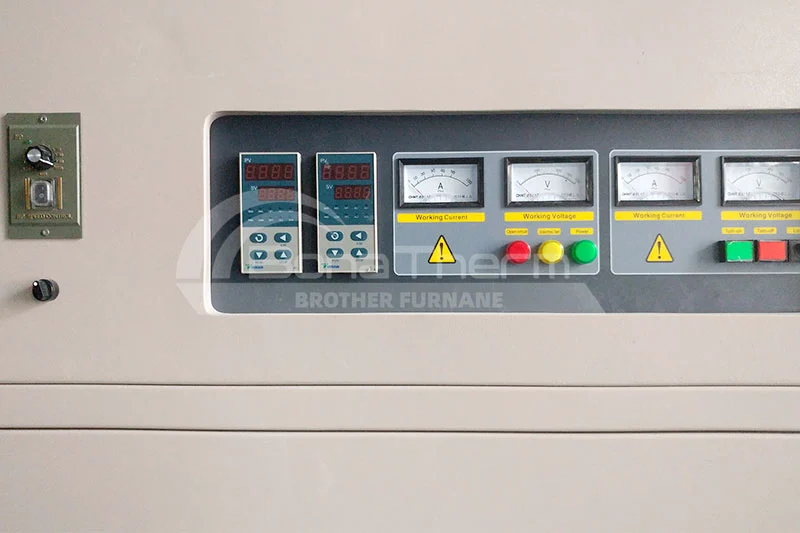

● 50 segments programmable and PID auto control

● Heating rate: 0~20 ℃/min

● Temperature accuracy: ±1 ℃

● Upper open furnace cover design for real-time observation of heated materials

● Furnace tilt angle 0 - 30 variable(also can be customized), it’s convenient for loading and unloading material

● Tube rotating Speed 3 - 7 RPM variable ( reversible), and there are 3 quartz lifting plates on the inner wall of the tube. When rotating, the material is fully turned over and evenly heated

● It has safe operation functions such as opening and closing power, over temperature alarm, and leakage protection

Standard Parts

● Tube plug 4 pcs;

● Thermocouple 1 pcs;

● Quartz tube 1 pcs;

● Vacuum pump 1 pcs;

● Vacuum flange 1 set;

● Vacuum pressure gauge 1 pcs

Technical Parameter

Model | Tube size (Thin end dia meter*Heating zone length) | Thick end diameter | Power | Max working temperature | Thermocouple | Tube material | Heating element |

|---|---|---|---|---|---|---|---|

BR-12NRT-60/300 |

60x300mm |

120mm |

3 KW |

1100oC |

K type |

Quartz tube |

Fe-Cr-Al-Mo wire |

BR-12NRT-60/450 |

60x450mm |

5 KW |

|||||

BR-12NRT-80/300 |

80x300mm |

150mm |

3 KW |

||||

BR-12NRT-80/450 |

80x450mm |

5 KW |

|||||

BR-12NRT-100/300 |

100x300mm |

180mm |

5 KW |

||||

BR-12NRT-100/450 |

100x450mm |

7 KW |

|||||

BR-12NRT-150/300 |

150x300mm |

200mm |

7KW |

||||

BR-12NRT-150/450 |

150x450mm |

9 KW |