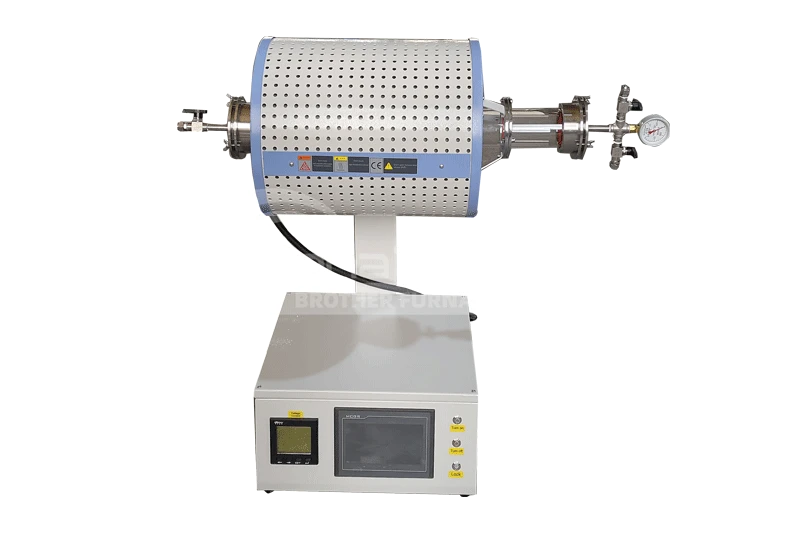

Product Description

The laboratory multi-station tube furnace is a high-performance experimental equipment that meets diverse research requirements. With a maximum operating temperature of up to 1700°C, it provides uniform and comprehensive heating for samples, ensuring optimal reaction conditions. This design is particularly well-suited for experiments that demand dynamic mixing or even heating, such as powder homogenization, catalytic reactions, and gas-phase processes. Constructed from high-strength, heat-resistant materials, the furnace has a precision temperature control system and efficient heating elements, ensuring exceptional reliability and operational flexibility for experimental applications.

Technical Parameters

Temperature Range | up to 1700°C |

Rotation Angle | Continuous 360° rotation with adjustable speed and direction |

Temperature Control Accuracy | ±1°C |

Tube Material | High-purity quartz, alumina, or corundum tubes |

Atmospheric Compatibility | Vacuum, inert gases, oxidizing atmospheres |

Power Rating | 3kW to 12kW (model-dependent) |

Control System | Touchscreen interface with support for 50-segment programmable heating |

Furnace Tube Size | 80*300mm(Can be customized) |

Key Features

360° Rotation for Enhanced Flexibility: The furnace tube can rotate continuously at any angle, allowing thorough mixing and uniform heating of samples without manual intervention.

Precision Temperature Control with Superior Performance: Incorporates an advanced PID temperature control system, offering an accuracy of ±1°C and supporting multi-segment programmable heating.

Uniform Heating for Greater Efficiency: High-quality heating elements combined with the rotational feature ensure consistent heat distribution, avoiding localized overheating or incomplete reactions.

Versatile Atmosphere Control: Compatible with various atmospheric conditions, including vacuum, inert gases, and oxidizing environments, to accommodate a wide range of experimental needs.

User-Friendly and Safe Operation: The furnace features an intuitive control panel and adjustable rotation settings for speed and angle. It is also equipped with comprehensive safety mechanisms to ensure secure operation.

Applications

Materials Science Research

Ideal for experiments involving powder homogenization, sintering, annealing, and coating.

Catalysis and Chemical Reactions

Particularly effective for dynamic stirring and pyrolysis in gas-solid and liquid-solid reaction processes.

Nanomaterial Fabrication

Optimizes nanoparticle morphology and uniformity through high-temperature rotational heating.

Gas-Phase Experiments

Supports studies such as gas decomposition, chemical vapor deposition (CVD), and other high-temperature gas-phase reactions.