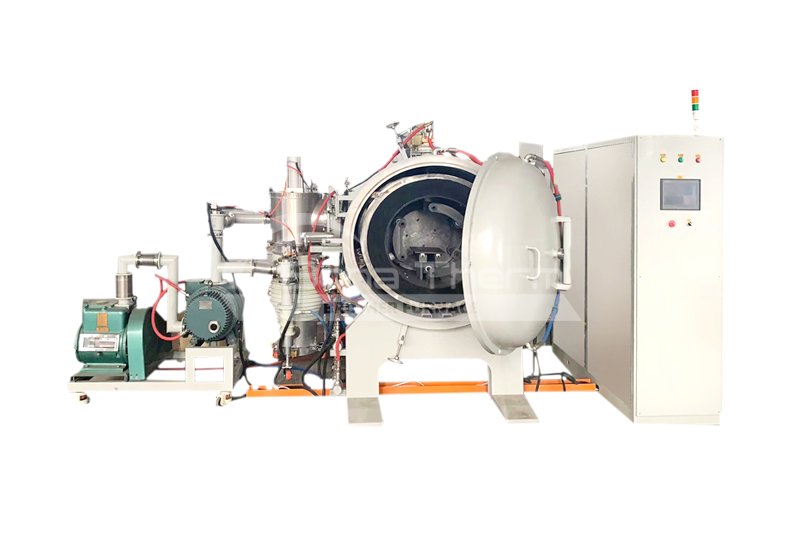

Introduction of Horizontal Graphite Vacuum Furnace

The vacuum graphite furnace from Brother Furnace is a high-performance, intelligent heating system developed by our engineers, integrating advanced temperature measurement, control technologies, smart features, new materials, and furnace chamber design from international expertise. Key to its design is the use of high-purity graphite furnace chambers, which provide exceptional heating uniformity and high-temperature performance up to 2200°C. Whether operating in a vacuum or under gas protection, this furnace ensures precise control and high-quality output during high-temperature processing.

|  |

Features of the Horizontal Graphite Vacuum Furnace

High-Temperature Performance:

The Brother Furnace graphite vacuum furnace utilizes high-quality graphite heating elements with a maximum temperature capability of 2400°C.

Insulation and Structure:

The furnace chamber is composed of a composite carbon fiber structure made from imported graphite felt and hard felt.

The inner layer of the furnace shell is polished stainless steel, while the outer layer is carbon steel, featuring a double-layer water-cooling system.

Intelligent Control:

The system features a high-definition touchscreen interface with a proprietary operating system.

An automated PLC control system ensures precise operation.

Operational Convenience:

The advanced front and rear door design facilitates easy loading and unloading of workpieces.

The furnace shell includes an observation window for monitoring the heating process.

Temperature Measurement Technology:

Dual temperature measurement is provided by tungsten-rhenium thermocouples and infrared thermometers, with the tungsten-rhenium thermocouple capable of automatic insertion and withdrawal.

Technical Parameters

model | Heating area (width*height*depth) ( mm ) | Working temperature (℃) | Power (kW) | Power supply ( V ) |

|---|---|---|---|---|

BR - 18GVF - 223 | 200*200*300 | 18 00 | 60 | 380 |

BR - 18GVF - 334 | 300*300*400 | 18 00 | 100 | 380 |

BR - 18GVF - 446 | 400*400*600 | 18 00 | 160 | 380 |

BR - 18GVF - 557 | 500*500*700 | 18 00 | 220 | 380 |

BR - 18GVF - 669 | 600*600*900 | 18 00 | 300 | 380 |

model | Heating area (width*height*depth) ( mm ) | Working temperature (℃) | Power (kW) | Power supply ( V ) |

|---|---|---|---|---|

BR - 22GVF - 223 | 200*200*300 | 2200 | 85 | 380 |

BR - 22GVF - 334 | 300*300*400 | 2200 | 150 | 380 |

BR - 22GVF - 446 | 400*400*600 | 2200 | 235 | 380 |

BR - 22GVF - 557 | 500*500*700 | 2200 | 315 | 380 |

BR - 22GVF - 669 | 600*600*900 | 2200 | 425 | 380 |