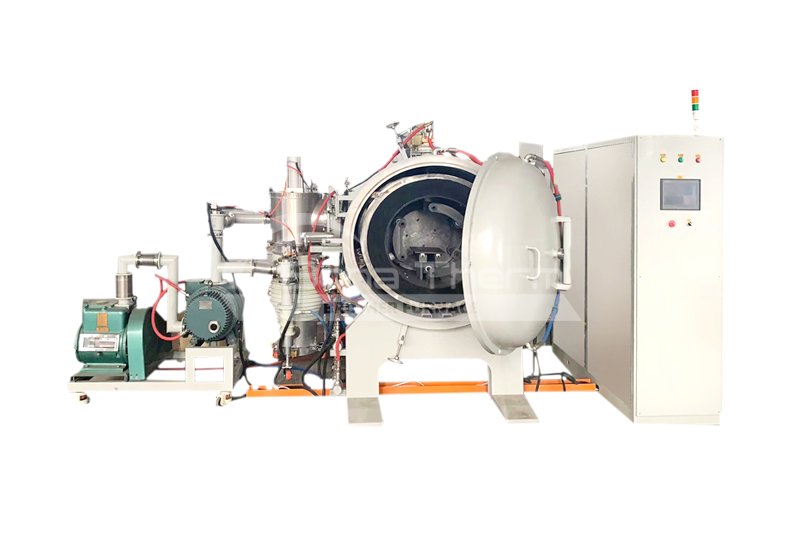

Vacuum Furnace

Brother Furnace vacuum furnaces are cost-effective, easy to operate, and offer excellent vacuum performance. Operating temperature up to 2300 ℃. They are widely used in various fields, including metal heat treatment, aerospace manufacturing, electronic component production, precision casting, and scientific research. The processes covered include sintering, debinding, quenching, tempering, annealing, brazing, nitriding, and carburizing. With their efficient and energy-saving design, our furnaces are an ideal choice for industries looking to improve product quality and production efficiency.

Application Process

· Quenching

· Annealing

· Tempering

· Brazing

· Sintering

· Debinding and Sintering

· Induction Melting

· Coating

· Nitriding and Carburizing

· etc.

Advantages of Brother Furnace's Vacuum Furnace

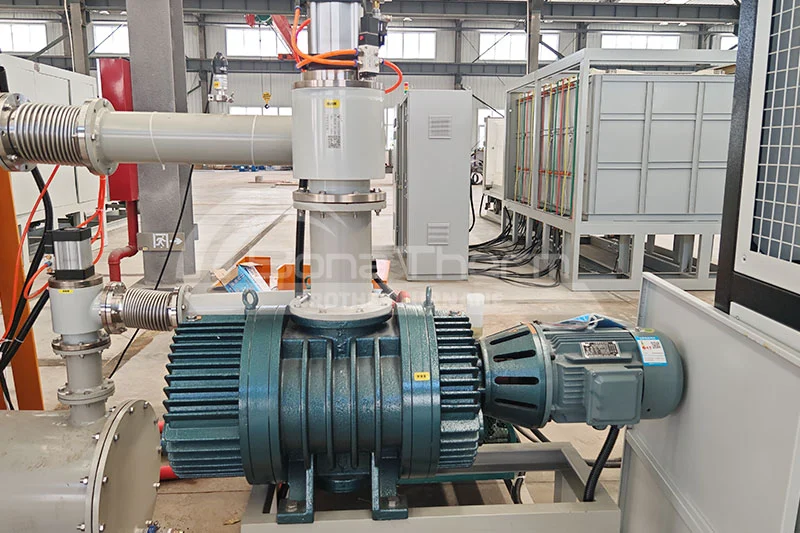

1. Outstanding Vacuum Performance High Ultimate Vacuum: Equipped with multi-stage vacuum pump systems (such as mechanical pumps, Roots pumps, diffusion pumps, etc.), achieving ultimate vacuum levels from 6x10⁻⁴ Pa to 7x10⁻³ Pa, meeting various high-vacuum requirements. Versatile Vacuum Systems: Configurable options available to suit different process requirements, ensuring stability and reliability of operations. |  |

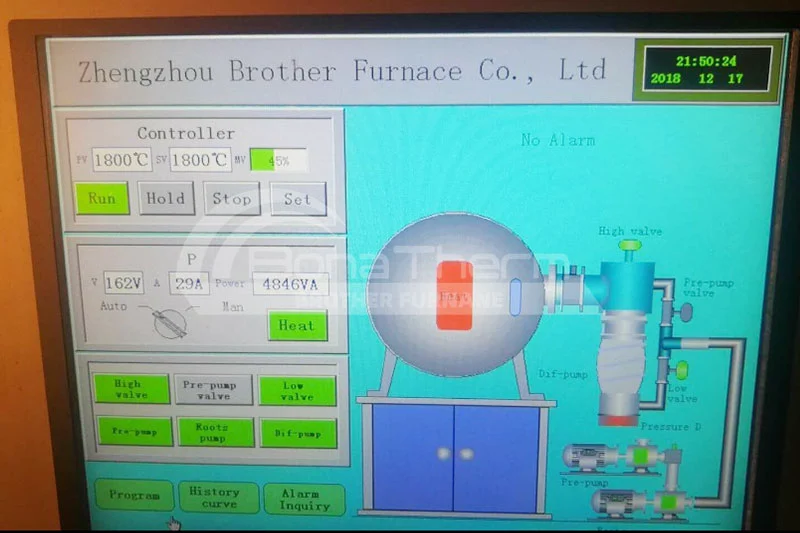

2. Wide Temperature Range Applicability High-Temperature Operation: The vacuum furnace offers selectable maximum temperatures ranging from 1200℃ to 2400℃, catering to different materials and processes such as melting, brazing, and sintering. Precise Temperature Control: Incorporates advanced temperature control technologies, including PLC automatic control systems and PID regulation, ensuring high-temperature uniformity (±5℃) and enhancing product quality. |  |

3. Multi-Functional Atmosphere Control Flexible Atmosphere Operation: Equipped with intake and exhaust ports, supporting the introduction of inert gases (such as nitrogen, argon, hydrogen, etc.) to prevent oxidation and contamination, suitable for various material processing requirements. Efficient Gas Cooling System: Features an internal high-pressure blower and heat exchanger for rapid cooling of workpieces, with high cooling rates that can bring temperatures down to a safe range in a short time. |  |

4. Energy Efficiency and Environmental Friendliness Low Energy Consumption Design: Utilizes alumina ceramic fiber chambers and advanced heating elements (such as resistance wires, molybdenum disilicide rods, graphite rods, etc.), ensuring efficient heating while reducing energy consumption. Dual-Layer Water Cooling Structure: Effectively reduces the surface temperature of the furnace shell (≤50℃), minimizing heat loss and enhancing operational safety. |  |

5. Automation and User-Friendly Operation Intelligent Control System: Equipped with a high-definition touchscreen, featuring a human-machine interface and a proprietary operating system developed by the company, supporting fully automatic and manual operation to simplify workflow. Safety and Reliability: Includes features such as upper limit alarms, deviation alarms, and automatic stops at the end of the program, ensuring safe operation even in unattended scenarios. |  |

6. Robust Structure and Aesthetic Design Premium Materials: Constructed from high-strength carbon steel and stainless steel, with an electrostatic powder-coated surface, ensuring durability and a visually appealing appearance. Optional Accessories and Flexible Design: Offers a range of optional accessories, such as chillers, rapid cooling systems, and stainless steel multi-layer racks, to meet various customer production needs. |  |

Technical Parameters

molybdenum thermal field

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHM-223 | 200*200*300 | 1350 | 34 | 380 |

BR-QHM-334 | 300*300*400 | 1350 | 60 | 380 |

BR-QHM-446 | 400*400*600 | 1350 | 98 | 380 |

BR-QHM-557 | 500*500*700 | 1350 | 132 | 380 |

BR-QHM-669 | 600*600*900 | 1350 | 180 | 380 |

heat-resistant steel hot field

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHS-223 | 200*200*300 | 750 | 12 | 380 |

BR-QHS-334 | 300*300*400 | 750 | twenty one | 380 |

BR-QHS-446 | 400*400*600 | 750 | 34 | 380 |

BR-QHS-557 | 500*500*700 | 750 | 46 | 380 |

BR-QHS-669 | 600*600*900 | 750 | 64 | 380 |

ceramic fiber thermal field(1200℃)

model | Maximum temperature(℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-12VF-1 | 1200 | 1100 | 100*100*100 | Resistance wire | 1 | 1.2 | 10Pa |

BR-12VF-5 | 1200 | 1100 | 150*150*200 | Resistance wire | 4.5 | 3.5 | 10Pa |

BR-12VF-12 | 1200 | 1100 | 200*200*300 | Resistance wire | 12 | 5 | 10Pa |

BR-12VF-36 | 1200 | 1100 | 300*300*400 | Resistance wire | 36 | 12 | 10Pa |

BR-12VF- 96 | 1200 | 1100 | 400*400* 6 00 | Resistance wire | 80 | 18 | 10Pa |

BR-12VF-1 7 5 | 1200 | 1100 | 500*500*700 | Resistance wire | 175 | 30 | 10Pa |

BR-12VF- 324 | 1200 | 1100 | 600*600*900 | Resistance wire | 324 | 50 | 10Pa |

BR-12VF- 768 | 1200 | 1100 | 800*800*1200 | Resistance wire | 768 | 80 | 10Pa |

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-12 H VF-1 | 1200 | 1100 | 100*100*100 | Resistance wire | 1 | 1.2 | 7x10-2Pa |

BR-12HVF-5 | 1200 | 1100 | 150*150*200 | Resistance wire | 4.5 | 3.5 | 7x10-2Pa |

BR-12HVF-12 | 1200 | 1100 | 200*200*300 | Resistance wire | 12 | 5 | 7x10-2Pa |

BR-12HVF-36 | 1200 | 1100 | 300*300*400 | Resistance wire | 36 | 12 | 7x10-2Pa |

BR-12HVF- 96 | 1200 | 1100 | 400*400* 6 00 | Resistance wire | 80 | 18 | 7x10-2Pa |

BR-12 H VF-1 7 5 | 1200 | 1100 | 500*500*700 | Resistance wire | 175 | 30 | 7x10-2Pa |

BR-12H VF - 324 | 1200 | 1100 | 600*600*900 | Resistance wire | 324 | 50 | 7x10-2Pa |

BR-12H VF - 768 | 1200 | 1100 | 800*800*1200 | Resistance wire | 768 | 80 | 7x10-2Pa |

ceramic fiber thermal field(1700℃)

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-17VF-1 | 1700 | 1600 | 100*100*100 | Silicon molybdenum rod | 1 | 1.5 | 10Pa |

BR-17VF-5 | 1700 | 1600 | 150*150*200 | Silicon molybdenum rod | 4.5 | 5 | 10Pa |

BR-17VF-12 | 1700 | 1600 | 200*200*300 | Silicon molybdenum rod | 12 | 8 | 10Pa |

BR-17VF-36 | 1700 | 1600 | 300*300*400 | Silicon molybdenum rod | 36 | 12 | 10Pa |

BR-17VF- 96 | 1700 | 1600 | 400*400*500 | Silicon molybdenum rod | 80 | 30 | 10Pa |

BR-17VF-1 7 5 | 1700 | 1600 | 500*500*700 | Silicon molybdenum rod | 175 | 45 | 10Pa |

BR-17VF- 324 | 1700 | 1600 | 600*600*900 | Silicon molybdenum rod | 324 | 66 | 10Pa |

BR-17VF- 768 | 1700 | 1700 | 800*800*1200 | Silicon molybdenum rod | 768 | 120 | 10Pa |

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-17H VF -1 | 1700 | 1600 | 100*100*100 | Silicon molybdenum rod | 1 | 1.5 | 7x10-2Pa |

BR-17HVF-5 | 1700 | 1600 | 150*150*200 | Silicon molybdenum rod | 4.5 | 5 | 7x10-2Pa |

BR-17HVF-12 | 1700 | 1600 | 200*200*300 | Silicon molybdenum rod | 12 | 8 | 7x10-2Pa _ |

BR-17HVF-36 | 1700 | 1600 | 300*300*400 | Silicon molybdenum rod | 36 | 12 | 7x10-2Pa |

BR-17HVF- 96 | 1700 | 1600 | 400*400*500 | Silicon molybdenum rod | 80 | 30 | 7x10-2Pa |

BR-17HVF-1 7 5 | 1700 | 1600 | 500*500*700 | Silicon molybdenum rod | 175 | 45 | 7x10-2Pa |

BR-17HVF- 324 | 1700 | 1600 | 600*600*900 | Silicon molybdenum rod | 324 | 66 | 7x10-2Pa |

BR-17H VF - 768 | 1700 | 1700 | 800*800*1200 | Silicon molybdenum rod | 768 | 120 | 7x10-2Pa |