Essential Components of Vacuum Furnace

BROTHER FURNACE

BROTHER FURNACE

2024-07-29 00:15

2024-07-29 00:15

When operating a vacuum furnace, it can be overwhelming to understand its complex structure. What are the different components, and what are their functions? This article will detail a vacuum furnace's key parts and roles.

Structure of a Vacuum Furnace

A vacuum furnace is more than just a simple chamber; it is a large and complex system composed of various components working together to perform heat treatment. A vacuum furnace usually includes a vacuum system, furnace body, heating system, water cooling system, and other structures.

Vacuum System

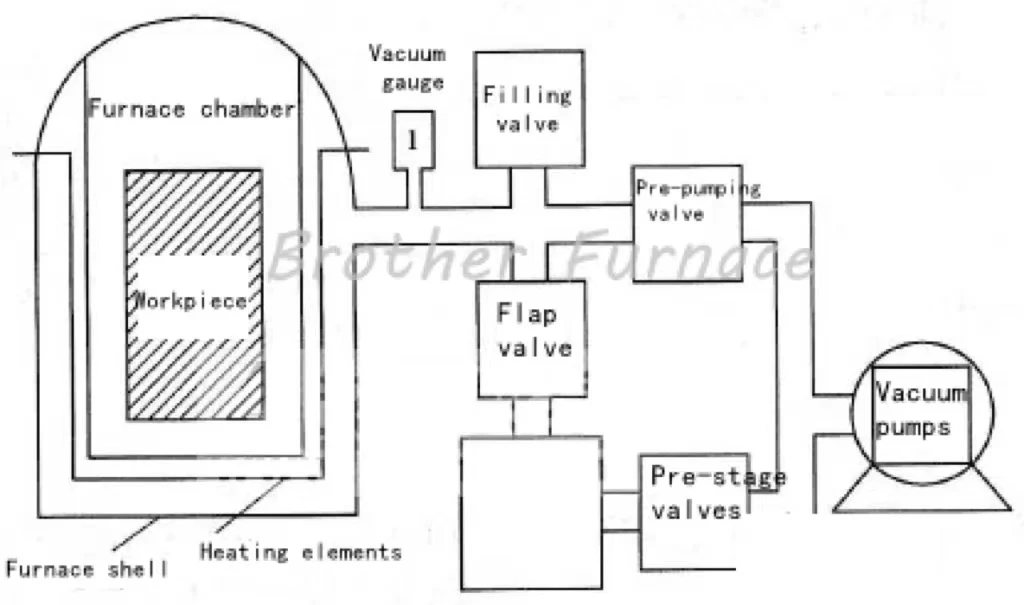

In my opinion, the most crucial part of a vacuum furnace is the vacuum system. Typically, the vacuum system of a vacuum heat treatment furnace consists of vacuum pumps, vacuum valves, vacuum gauges, baffles, cold traps, and pipelines. Its primary function is to evacuate the air and gases from the furnace chamber, creating a vacuum environment.

Furnace Body

The furnace body is the main space for heat treatment, capable of housing the materials to be processed and maintaining stable internal temperatures through insulation layers. It is usually made of stainless steel, ceramic, or graphite. The furnace body directly affects the furnace's heat resistance and sealing, ensuring safety and stability under high temperatures.

Heating System

The heating system mainly includes the temperature control system, heating elements, and power supply.

Temperature Control System: Typically equipped with a Programmable Logic Controller (PLC) and a touchscreen interface for pre-programmed temperature/time profiles.

Heating Elements: Efficient and stable heating elements ensure uniform heating of materials during the heat treatment, avoiding quality issues due to temperature differences.

Power Supply: Ensures precise temperature control, which is crucial for achieving the desired material properties and quality of the processed materials.

Water Cooling System

The water cooling system consists of stainless steel stop valves, water inlets, drain tanks, hydraulic electric contact pressure gauges, etc.. It needs to be connected to the user’s circulating water system. It controls the temperature of the furnace body and heating elements to prevent overheating.

Brother Furnace's Vacuum Furnaces

As a leading manufacturer of vacuum furnaces, Brother Furnace has over 20 years of experience in vacuum furnace production. We understand every part of the vacuum furnace and have provided perfect vacuum solutions to over 5000 clients.

If you need a vacuum furnace solution, please click to email us or leave a message to get assistance.