Do You Know the Metal Annealing Process?

BROTHER FURNACE

BROTHER FURNACE

2024-03-28 23:06

2024-03-28 23:06

In the process of manufacturing metal products, the physical properties of the metal play a vital role in the quality and performance of the final product. However, since problems such as internal stress and uneven grain structure may occur during metal processing and forming, some measures need to be taken to improve the structure and performance of the metal. Among them, one of the widely used methods is the metal annealing process, which can restore the uniform structure and properties of the metal, thereby improving its mechanical properties, corrosion resistance and processability.

What is metal annealing?

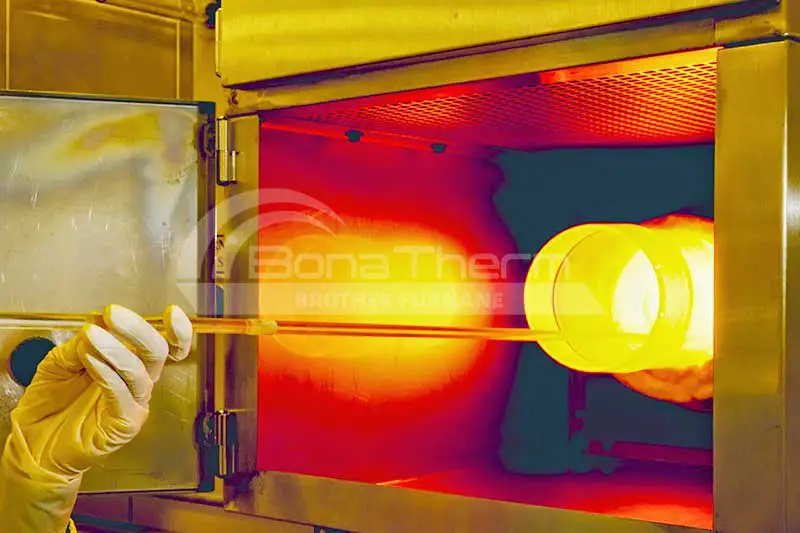

Metal annealing is a heat treatment process that changes its grain structure and internal stress by heating the metal to a certain temperature and then gradually cooling it. During the annealing process, the grains of the metal will be rearranged and internal stresses will be released, thereby improving the properties of the metal.

Types of annealing

Full annealing

Full annealing is a metal heating treatment method that heats the metal to a high enough temperature and then cools it in natural air. This method is widely used in processing harder metals, with the primary purpose of achieving maximum grain growth and internal stress relief.

Normalizing

Normalizing involves heating the metal to a higher temperature and then cooling it slowly. This process is often used on medium-hard metals and has the advantage of balancing the hardness and toughness of the metal.

Annealing Softening

Annealing softening is a metal treatment method achieved by heating the metal to a high temperature and then cooling it rapidly. This method can effectively reduce the hardness of the metal, thereby improving its plasticity and workability.

Aging treatment

Aging treatment is to heat the metal to a lower temperature and maintain it for a period of time after annealing, and then cool it. This method is often applied to alloys to further improve their strength and corrosion resistance.

Protective gas

The high temperature during annealing will cause oxidation and peeling of the metal surface. To prevent peeling, annealing can be performed under a protective gas, such as an endothermic gas (a mixture of carbon monoxide, hydrogen and nitrogen). Annealing can also be performed with a mixture of nitrogen and hydrogen. carried out in the synthesized gas.

What equipment is suitable for metal annealing?

Traditionally, for materials to be annealed , vacuum annealing furnaces, mesh belt annealing furnace, trolley annealing furnace are usually used . Brother Furnace provides return processing solutions for various metal materials under atmosphere protection. If you are interested, please contact us!