Introduction

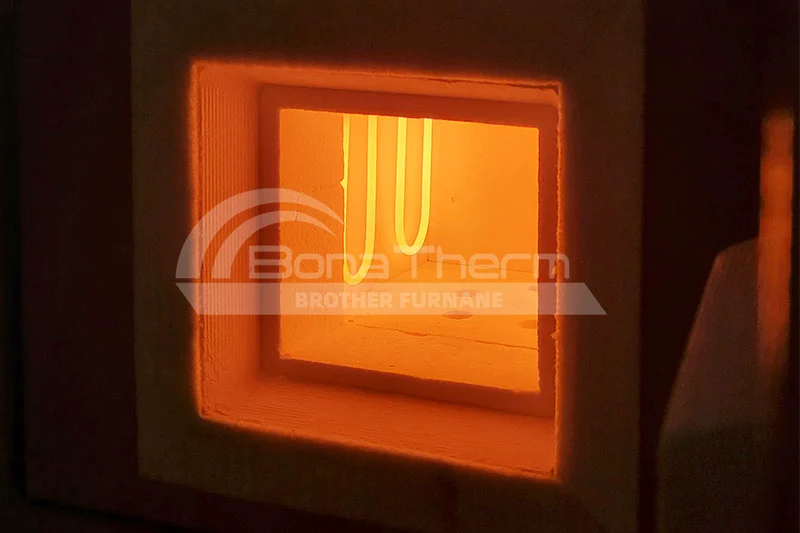

Dental muffle furnace uses high-purity polycrystalline mullite fiber as the furnace material. It is light in weight, compact in size, and has a power of only 1.5 kW. It is suitable for use in small laboratories and even home-style working environments. It is mainly used for sintering, sintering, and sintering dental dentures such as crowns, bridges, and implants.

Maintain

Regular cleaning and maintenance are key to keeping your dental furnace working reliably over the long term. Users need to regularly check heating elements, insulated furnaces, and control systems to ensure their normal working conditions.Standard Accessories

A silicon molybdenum rod, a corundum crucible, a pack of zirconium beads, and a fireproof brick.

Features

- It is specially designed for the sintering of small batch samples in laboratories such as zirconia denture crystallization, structural ceramics, and polymer ceramics.

- The power is only 1.5 KW, no special high-power circuit is required, and the circuit in the home can be used.

- The heating speed is fast, adjustable from 0-40℃/minute.

- The 7-inch high-definition touch screen is easy to operate and can store 30 different process programs.

Technical Parameters

Furnace size | 100*100*100mm (width*height*depth) |

maximum temperature | 1700℃ (not more than 2 hours) |

Operating temperature | 1600℃ |

Temperature control method | Intelligent 50-segment programmable control |

Thermocouple | Type B |

Temperature control accuracy | +/-1℃ |

rated power | 1.5kW |

net weight | 58kgs |

Dimensions | 410x380x610mm |

Get Inquiry

Get Inquiry Send Email

Send Email