Introduction

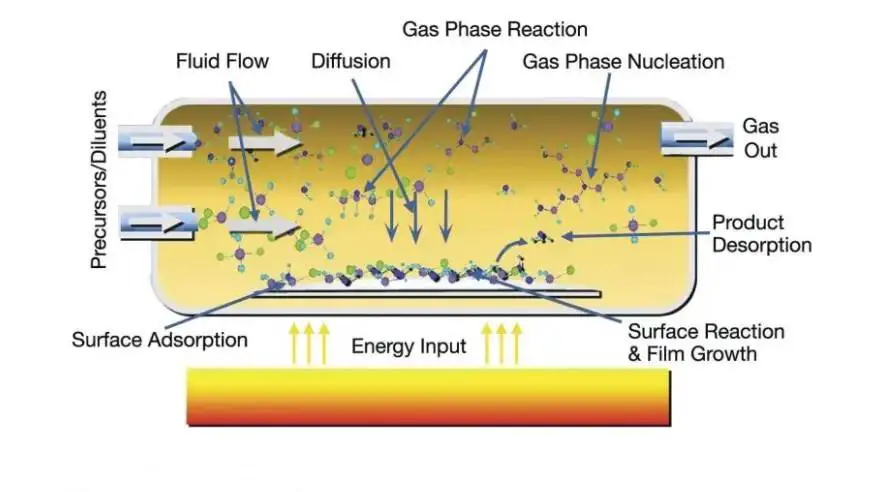

Brother Furnace's CVD/PECVD tube furnace is an advanced material synthesis equipment designed for chemical vapor deposition (CVD) processes widely used in semiconductors, optoelectronics, new materials, and surface coatings. Our CVD tube furnace excels in temperature control, gas management, and energy efficiency, and is designed to meet the requirements of high-performance and high-precision material production.

|  |  |

Features

● Maximum temperature: 1200℃ (HRE resistance wire heating).

● Intelligent 50-segment programmable automatic control.

● Over-temperature protection function, automatic power off when the temperature exceeds the allowable set value.

● Safety protection: automatic power off when the furnace leaks electricity.

● Furnace shell structure, double-layer air-cooled structure; surface temperature is lower than 50℃.

● The furnace chamber adopts high-quality alumina polycrystalline fiber inorganic material formed by vacuum adsorption of Japanese technology, with excellent thermal insulation performance.

● 304 stainless steel KF quick-release sealing flange.

● Heating rate ≦20℃/min.

● Temperature control accuracy ±1℃.

● High film deposition rate: RF glow technology greatly improves the deposition rate of the film, and the deposition rate can reach 10Å/S.

● High uniformity over a large area: Advanced multi-point RF feed-in technology, special gas path distribution, and heating technology are adopted, so that the film uniformity index reaches 8%.

● High consistency: Using the advanced design concept of the semiconductor industry, the deviation between each substrate deposited at one time is less than 2%.

● High process stability: Highly stable equipment ensures the continuity and stability of the process.

● Standard direct-connected vacuum pump, the ultimate vacuum degree can reach 10Pa.

Application Areas

Semiconductor material preparationPhotoelectric material synthesis

New coating research and development

Nanomaterial preparation

Material science research

|

Thin Film Deposition |

Technical Parameters

| CVD chemical vapor deposition system | |

| Product number | BR-CVD/PECVD |

| slide | With a slide, the furnace can be slid to achieve rapid heating or cooling function |

| Heating zone length | 400mm single temperature zone/dual temperature zone |

| Furnace tube size | Diameter 60x1200mm outer diameter x length |

| Furnace tube material | High-purity quartz tube |

| Operating temperature | ≤1100℃ |

| Temperature Control System | Artificial intelligence PID instrument, automatic temperature control |

| Temperature control accuracy | ±1℃ (with over-temperature and couple-off alarm functions) |

| Heating rate | Recommended 0~10℃/min |

| Heating element | High-quality resistance wire |

| Vacuum system | |

| Rated voltage | Single phase 220V 50Hz |

| Passable gas | Inert gases such as nitrogen and argon |

| Temperature measuring element | Thermocouple temperature measurement |

| Shell structure | Double-layer shell structure with air cooling system |

| vacuum flange | It has an air inlet and a pressure control valve, pneumatic pressure relief valve and air release valve at the other end. |

| Air supply system | Four-way precision proton flow meter, adjust gas flow through touch screen |

| Vacuum system | Rotary vane pump, the vacuum degree can reach 1pa in the cold state of the empty furnace. Vacuum gauge: Imported digital display vacuum gauge displays the vacuum degree in real time with high accuracy. |

| Gas dosing system | The overall pressure range can be controlled -20kpa to 20kpa (relative pressure) |

| Rated voltage | Single phase 220V 50Hz |

| RF power supply (PECVD only) | |

| Signal frequency | 13.56MHz±0.005% |

| Power output range | 500W |

| Maximum reflected power | 500W |

| RF output interface | 50Ω, N-type, female |

| Power stability | ±0.1% |

| harmonic components | ≤-50dbc |

| Supply voltage | Single-phase AC (187V-253V) frequency 50/60HZ |

| Overall machine efficiency | >=70% |

| Power Factor | >=90% |

| cooling method | Forced air cooling |

model | Furnace tube diameter x heating zone length ( mm ) | Furnace tube length (mm) | Power ( kW ) | Maximum temperature (℃) | gas control | Vacuum degree (Pa) |

BR-CVD-60 | Φ 60×400 | 1200 | 3 | 1200 | 3 way | 10Pa/7x10-3 |

BR-CVD-80 | Φ 80×400 | 1200 | 4 | 1200 | 3 way | 10Pa/7x10-3 |

BR-CVD-100 | Φ 80×400 | 1200 | 6 | 1200 | 3 way | 10Pa/7x10-3 |

model | Furnace tube diameter x heating zone length mm | Power ( kW ) | Maximum temperature Maximum temperature (℃) | RF power supply | gas control | Vacuum degree (Pa) | |

frequency | power | ||||||

BR-PECVD-60 | Φ 60×450 | 4 | 1200 | 13.56MHz±0.005% | 300-500W | 3 way | 10Pa/7x10-3 |

BR-PECVD-80 | Φ 80×450 | 5 | 1200 | 3 way | 10Pa/7x10-3 | ||

BR-PECVD-100 | Φ 100×450 | 7 | 1200 | 3 way | 10Pa/7x10-3 | ||