Introduction

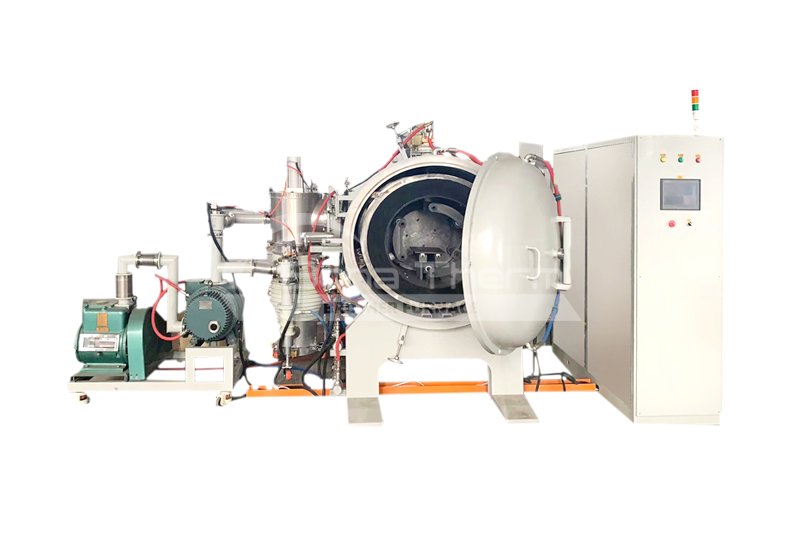

Cobalt-chromium alloy vacuum annealing furnace is a kind of equipment specially used for annealing cobalt-chromium alloy, heating and slowly cooling the alloy in a vacuum environment to improve its physical and mechanical properties.

Titanium alloy/cobalt-chromium alloy vacuum annealing furnace | |

|---|---|

Furnace chamber size | 180x350mm (furnace tube outer diameter x heating zone length ) |

Maximum operating temperature | 1200℃ |

Long-term working temperature | 0-1100°C |

Voltage and rated power | 22 0V 50HZ 6KW |

Fully automatic touchscreen | 7-inch LCD touch screen, real-time display of heating curve |

Temperature control accuracy | ±1°C |

Heating rate | Recommended heating rate <20°C/min |

Vacuum degree | 99KPa |

Heating element | Molybdenum resistance wire |

Furnace shell/furnace | Three layers of full fiber lining constitute the entire furnace Made of high-strength carbon steel, pickled and phosphated for rust removal, electrostatic spraying, beautiful double-layer air-cooled furnace shell, the surface temperature of the furnace shell is lower than 50℃ Japan Mitsubishi furnace door sealing fiber strip |

|  |

Characteristics of Cobalt-Chromium Alloy

Cobalt-chromium alloy is widely used in dentistry, medical implants, aerospace, and industrial coatings due to its high strength, corrosion resistance, and biocompatibility. Common cobalt-chromium alloys include cobalt-chromium-molybdenum alloys and cobalt-chromium-tungsten alloys.

Purpose of Annealing

Annealing is a heat treatment process that reduces internal stress and improves ductility and microstructure by heating and slowly cooling the metal, thereby enhancing the material's mechanical properties and corrosion resistance. For cobalt-chromium alloy, annealing can:

Reduce internal stress: reduce residual stress generated during processing.

Improve ductility and toughness: make the alloy less likely to break or crack during use.

Improve corrosion resistance: enhance the corrosion resistance of the alloy by optimizing the microstructure.