-

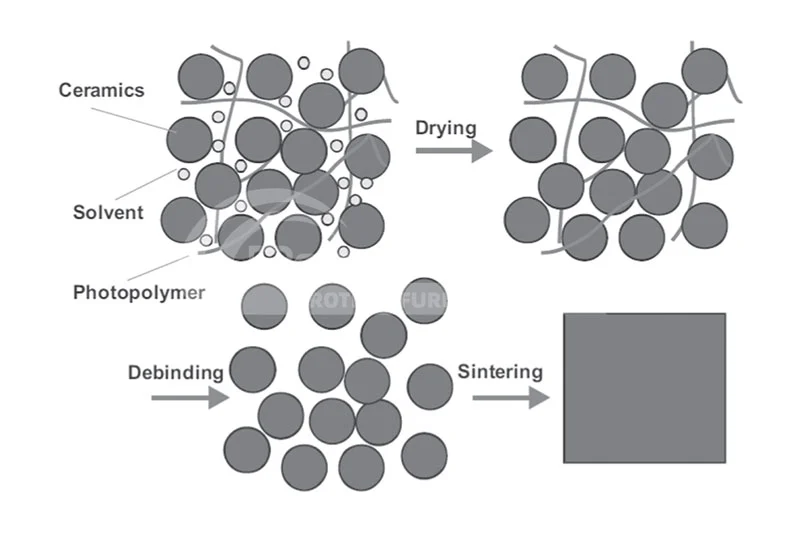

Debinding and Sintering of Ceramics

BROTHER FURNACE

BROTHER FURNACE 05 Dec,2024

05 Dec,2024

Ceramic materials are widely recognized for their exceptional mechanical properties, thermal stability, and resistance to wear and corrosion. These qualities make them indispensable in the aerospace,

VIEW MORE >> -

Bright Annealing of 316L Stainless Steel in Vacuum Furnace

BROTHER FURNACE

BROTHER FURNACE 28 Nov,2024

28 Nov,2024

Due to its exceptional corrosion resistance, 316L stainless steel is widely used in industries such as chemicals, food, and pharmaceuticals. Bright annealing is a key heat treatment process that further enhances its performance and durability.

VIEW MORE >> -

Benchtop Furnace

BROTHER FURNACE

BROTHER FURNACE 21 Nov,2024

21 Nov,2024

A benchtop furnace is a compact high-temperature furnace designed for laboratory use. Despite its small size, it can reach temperatures up to 1700°C or higher, making it suitable for material testing, heat treatment, sintering, and other applications.

VIEW MORE >> -

How to Address Vacuum Level Decline in Vacuum Furnaces? Maintenance Tips and Solutions

BROTHER FURNACE

BROTHER FURNACE 12 Nov,2024

12 Nov,2024

Vacuum furnaces are essential for processing materials under high temperatures and are widely used in metal heat treatment, brazing, sintering, and other applications. However, with prolonged use, a vacuum furnace’s vacuum level may gradually decline, impacting heating efficiency and product quality.

VIEW MORE >> -

Alumina Tube Furnace or Quartz Tube Furnace? How to Choose the Right Furnace

BROTHER FURNACE

BROTHER FURNACE 05 Nov,2024

05 Nov,2024

In high-temperature heat treatment and laboratory applications, tube furnaces are essential tools. Among the most common types are alumina tube furnaces and quartz tube furnaces, each with distinct

VIEW MORE >> -

Graphite's Role and Advantages in Vacuum Furnaces

BROTHER FURNACE

BROTHER FURNACE 04 Nov,2024

04 Nov,2024

Graphite has emerged as an ideal chamber material due to its high-temperature resistance, chemical stability, and excellent thermal conductivity. This article will explore the connection between vacuum furnaces and graphite chambers, analyze the main advantages of using graphite, examine its application scenarios, and introduce Brother Furnace's professional solutions in graphite chambers.

VIEW MORE >>

- Home

- Products

- Vacuum Furnace

-

Muffle Furnace

- 200℃-1800℃ Laboratory Box Muffle Furnace

- Box Muffle Furnace up to 1200℃

- Box Muffle Furnace up to 1400℃

- Box Muffle Furnace up to 1700℃

- Box Muffle Furnace up to 1800℃

- Industrial Muffle Furnace

- Muffle Ashing Furnace

- Controlled Atmosphere Muffle Furnace

- Crucible Muffle Furnace

- Muffle Furnace with Observation Window

- Double Door Muffle Furnace

- Dental Muffle Furnace

- PC-Controlled Muffle Furnace

- Customized Box/Muffle Furnace

-

Tube Furnace

- Horizontal Tube Furnace

- Vertical Tube Furnace

- Rotary Tube Furnace

- Slide-Rapid Cooling Tube Furnace

- Vacuum Tube Furnace

- Laboratory Multi-Station Tube Furnace

- CVD/PECVD Tube Furnace

- (Double/three/five temperature zones)Multi-Temperature Zone Tube Furnace

- Double-Tube Tube Furnace

- Customized Tube Furnace

-

Atmosphere Furnace

- Atmosphere Furnace up to 1700℃

- Hydrogen Atmosphere Furnace

- External Heating Atmosphere Furnace

- Atmosphere Hot Press Furnace

- 1400°C Touchscreen Atmosphere Furnace (200×200×200 mm)

- Inert Atmosphere Furnace

- 1200°C Atmosphere Furnace (400×400×400 mm)

- Nitrogen Atmosphere Furnace

- 1400°C Atmosphere Furnace (300×300×300 mm)

- 1200°C Atmosphere Furnace (200×200×300 mm)

- Debinding and Sintering Furnace

- Lifting Bottom Furnace

- Bogie Hearth Furnace

- Dental Furnace

- Application

- Case

- Blog

- About

- Contact