Choose Your Atmosphere Furnace Here

-

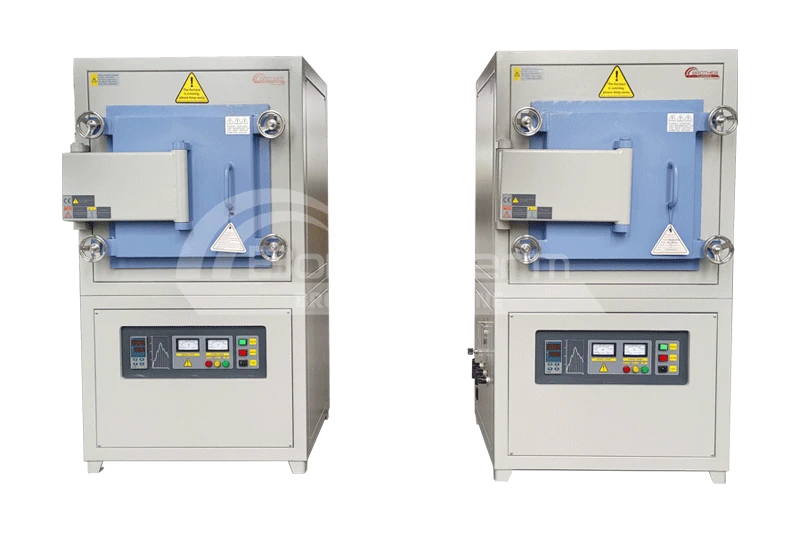

Atmosphere Furnace up to 1700℃

View Products+

-

Hydrogen Atmosphere Furnace

View Products+

-

External Heating Atmosphere Furnace

View Products+

-

Atmosphere Hot Press Furnace

View Products+

-

1400°C Touchscreen Atmosphere Furnace (200×200×200 mm)

View Products+

-

Inert Atmosphere Furnace

View Products+

-

1200°C Atmosphere Furnace (400×400×400 mm)

View Products+

-

Nitrogen Atmosphere Furnace

View Products+

-

1400°C Atmosphere Furnace (300×300×300 mm)

View Products+

-

1200°C Atmosphere Furnace (200×200×300 mm)

View Products+

Leave message now!

Brother Furnace Atmosphere Furnace Application Cases

Application Cases | Specific Process | Equipment Configuration |

|---|---|---|

Metal Heat Treatment | Titanium Alloy Vacuum Annealing | Pre-vacuum box atmosphere furnace (standard rotary vane vacuum pump) + silicone gasket sealing system |

Ceramic Sintering | Silicon Nitride Ceramic Gas Pressure Sintering | Alumina polycrystalline fiber furnace chamber (standard) + nitrogen gas path system (optional float/proton flow meter) |

Electronic Packaging | Chip Brazing (Oxygen-Free Copper Welding) | Fully enclosed box atmosphere furnace (12mm square steel reinforcement structure) + micro-oxygen control module (requires optional 2-way/3-way gas path system) |

Automotive Manufacturing | Gear Carburizing Quenching | Double-layer steel plate furnace body (standard PID temperature control) + carbon potential control expansion kit (requires optional touchscreen software) |

Photovoltaic Materials | Solar Silicon Wafer Phosphorus Diffusion | Box-type atmosphere furnace (standard 50-step programming) + exhaust gas treatment system (requires optional direct connection vacuum pump) |

Common Questions of Atmosphere Furnace

-

What Is An Atmosphere Furnace?

Atmosphere furnace is a high-temperature device designed to control the atmosphere within its chamber, such as inert gases, reducing gases, or vacuum, to prevent oxidation, decarburization, or promote specific chemical reactions.

-

What Are The Common Applications Of An Atmosphere Furnace?

Atmosphere furnaces are widely used in processes such as heat treatment, sintering, annealing, and welding, with primary applications in material processing, metal refining, and laboratory research.

-

What Is The Temperature Range Of An Atmosphere Furnace?

The operating temperature range of an atmosphere furnace typically ranges from 1000°C to 1700°C, depending on the furnace type and user requirements.

-

How Does An Atmosphere Furnace Control The Atmosphere?

An atmosphere furnace controls the internal atmosphere by introducing specific gases or maintaining a vacuum, ensuring material stability and quality during the processing.

-

What Type Of Gases Are Required To Operate An Atmosphere Furnace?

Atmosphere furnaces can use various gases, including nitrogen, argon, hydrogen, or other specialized gases, depending on the material and processing requirements.

-

What Safety Precautions Should Be Taken When Using An Atmosphere Furnace?

When using an atmosphere furnace, it is important to ensure the correct gas flow, avoid gas leaks, follow safety operating procedures, and regularly inspect the furnace and control systems for proper functionality.

Brother Furnace's Qualification Certificate