Introduction

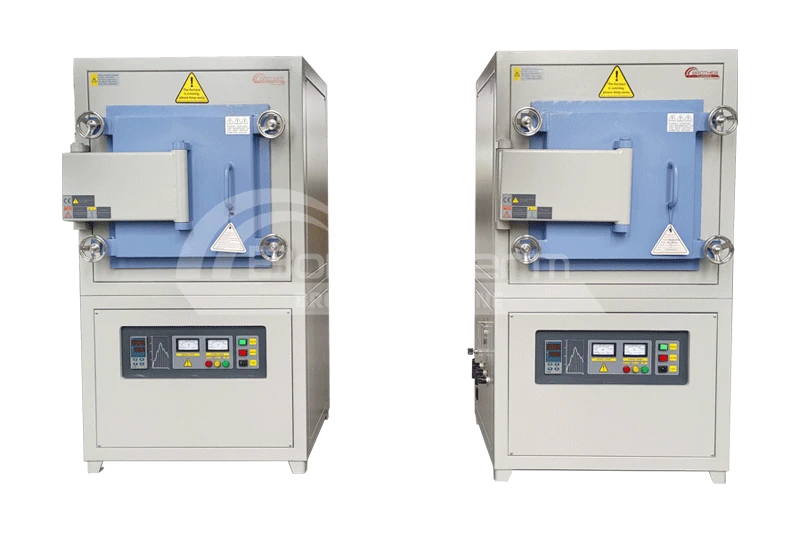

This 1200°C atmosphere furnace, with a chamber size of 200×200×300 mm, features an innovative vertical design, making it suitable for processing elongated or irregularly shaped workpieces. Its compact size and exceptional performance cater to diverse needs in both research and industrial applications.

Features

· Vertical Chamber Design: Optimized for processing tall or irregularly shaped workpieces.

· Reliable Temperature Control: PID controller ensures continuous and precise heating.

· Atmosphere Flexibility: Supports various gas environments to meet anti-oxidation processing requirements.

· Space-Saving Design: Ideal for laboratories with limited space.

· Cost-Effective: Delivers high performance while reducing energy consumption.

Technical Parameters

Device model | Maximum temperature (℃) | Working temperature (℃) | Furnace size (width*height*depth) ( mm ) | Voltage(V) | Power ( kW ) |

|---|---|---|---|---|---|

BR-12AN-2 | 1200 | 1100 | 120*120*130 | 220 | 1.2 |

BR-12AN-3 | 1200 | 1100 | 150*150*150 | 220 | 2.5 |

BR-12AN-5 | 1200 | 1100 | 150*150*200 | 220 | 3 |

BR-12AN-8 | 1200 | 1100 | 200*200*200 | 220 | 5 |

BR-12AN-12 | 1200 | 1100 | 200*200*300 | 220 | 6 |

BR-12AN-27 | 1200 | 1100 | 300*300*300 | 380 | 8 |

BR-12AN-36 | 1200 | 1100 | 300*300*400 | 380 | 10 |

BR-12AN-64 | 1200 | 1100 | 400*400*400 | 380 | 16 |

Applications

· Material Synthesis: Development of new materials in research settings.

· Small Component Heat Treatment: Perfect for annealing or brazing.

· Specialized Tasks: Supports unique heat treatment processes requiring precise gas environments.

· Educational and Industrial Research: Widely used in academic institutions and industrial R&D.