Introduction

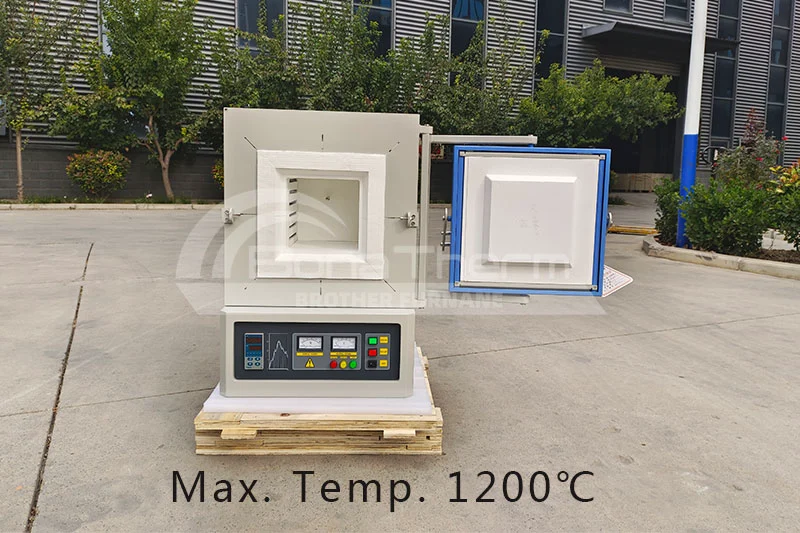

1200℃ muffle furnace uses polycrystalline mullite fiber lining, and total thickness is 120-250mm, to ensure very good thermal effect. Double layer of furnace shell with fan cooling, surface temperature is less than 60℃, strength structured furnace roof, to ensure long life to avoid any collapse from continuous working. The furnaces is a special equipment specially developed for the sintering, melting and analysis of metal, non-metal and other compound materials in laboratories and industrial and mining enterprises of universities and research institutes.

Feature (1200 type)

● Max working temperature RT~1200℃

● Volume 1~1000L

● High quality Fe-Cr-Al-Mo resistance wire

● The upper door and the side door can be customized to keep the operator away from the heat source

● 50 segments programmable and PID auto control

● With over temperature alarm function

● Cooling fan can reduce the temperature of the casing

Accessories

Standard Parts: High temperature gloves; Crucible clip; Operation Manual

Optional Parts: 7 inch touch screen; Gas Vent; Observation Hole; Furnace Furniture; Alumina crucible; Software

Video of Muffle Furnace

Technical Parameter (1200 type)

Model | Max temperature(°C) | Inner size (W *H * D) mm | Volume (L) | Power (KW) | Phase | Thermocouple |

|---|---|---|---|---|---|---|

BR-12N-1 | 1200 | 100*100*100 | 1 | 0.8 | 1 | K type |

BR-12N-2 | 1200 | 120*120*130 | 2 | 1.2 | 1 | K type |

BR-12N-3 | 1200 | 150*150*150 | 3 | 2.5 | 1 | K type |

BR-12N-5 | 1200 | 150*150*200 | 5 | 3 | 1 | K type |

BR-12N-8 | 1200 | 200*200*200 | 8 | 5 | 1 | K type |

BR-12N-12 | 1200 | 200*200*300 | 12 | 6 | 1 | K type |

BR-12N-27 | 1200 | 300*300*300 | 27 | 8 | 1 | K type |

BR-12N-36 | 1200 | 300*300*400 | 36 | 10 | 3 | K type |

Get Inquiry

Get Inquiry Send Email

Send Email